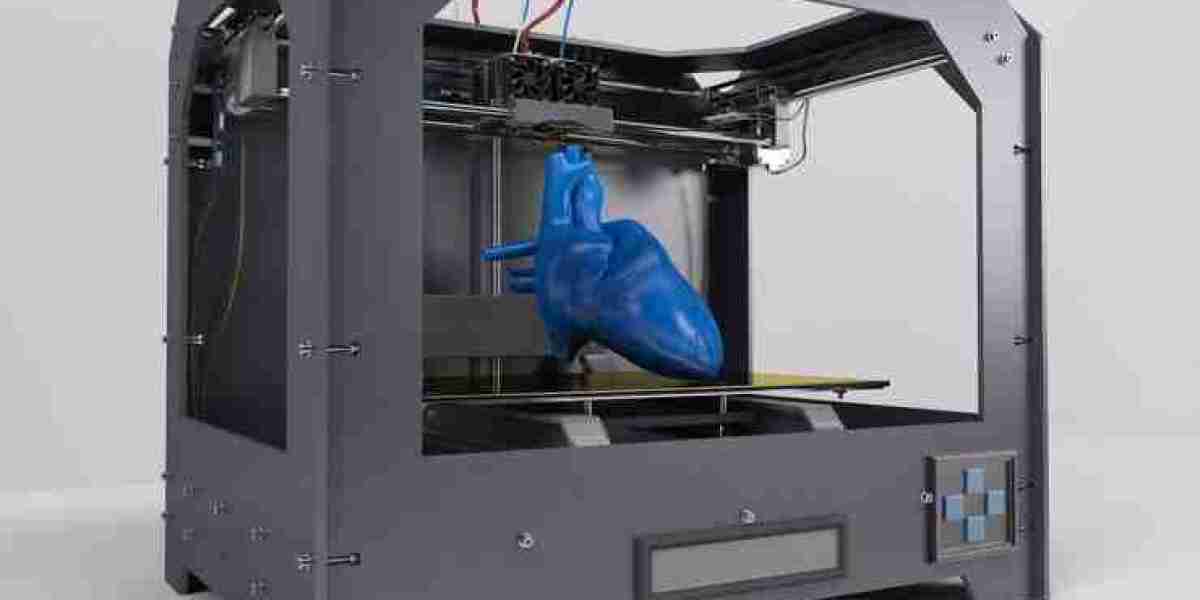

The desktop 3D printer market has experienced a substantial evolution over the past decade, transforming how industries approach design, prototyping, and manufacturing. With technological advancements and increased accessibility, desktop 3D printers have found solutions to many of the challenges faced by industries ranging from education to healthcare, automotive, and manufacturing. These solutions have brought about increased efficiency, reduced costs, and improved customization, enabling businesses to innovate and scale operations. This article explores the key solutions that desktop 3D printers offer across various industries.

1. Rapid Prototyping and Product Development

One of the primary solutions offered by desktop 3D printers is rapid prototyping. Traditionally, prototyping could be a lengthy and expensive process, requiring the development of molds or tooling. With desktop 3D printers, manufacturers can quickly produce a prototype or a model that can be tested and refined. This accelerates the product development cycle, reducing both time and costs. Designers and engineers now have the ability to create and test multiple iterations of a product in a fraction of the time it would take using conventional methods, fostering innovation and improving the final product.

2. Customization and Personalization

Desktop 3D printing offers unparalleled customization capabilities. From custom-fit medical devices to personalized consumer goods, the ability to create tailored products on-demand is one of the most attractive solutions of desktop 3D printers. In the healthcare industry, 3D printers are used to create custom prosthetics and implants that fit a patient’s unique anatomy. This personalization not only improves the quality of life for patients but also reduces costs associated with mass-produced solutions. In consumer goods, 3D printing allows for bespoke products such as customized jewelry, footwear, and fashion accessories, meeting the growing demand for individuality in the marketplace.

3. Small-Batch and On-Demand Manufacturing

Desktop 3D printers enable small businesses and entrepreneurs to manufacture products on-demand without the need for large-scale production runs. Traditional manufacturing methods often require minimum order quantities that can be expensive for small batches. Desktop 3D printers solve this by enabling small, on-demand production runs of products at lower costs. Whether it’s creating customized tools, spare parts, or niche consumer goods, businesses can leverage desktop 3D printers to manufacture products as needed, avoiding inventory costs and reducing waste. This solution is particularly beneficial for startups, independent designers, and makers who require small quantities of products without the overhead of traditional manufacturing.

4. Educational Tools and Learning

Desktop 3D printers have proven to be valuable tools in educational settings, offering unique solutions to the challenges of teaching and learning. These printers enable students to turn their ideas into tangible objects, fostering creativity, critical thinking, and problem-solving skills. In STEM (Science, Technology, Engineering, and Mathematics) education, 3D printing allows students to create models of complex concepts, such as molecular structures or engineering designs, providing hands-on experiences that enhance understanding. Furthermore, 3D printing enables the creation of interactive educational materials, which can be used to engage students and deepen their knowledge in various subjects.

5. Cost-Effective Low-Volume Production

Desktop 3D printers provide a solution to the need for cost-effective low-volume production. In industries where low-volume, highly customized products are required, traditional manufacturing processes may not be economically feasible. Desktop 3D printers enable businesses to produce these products in small quantities, reducing upfront costs while still offering high-quality output. The ability to print low-cost, functional parts in small batches opens up new possibilities for product customization and short-run manufacturing, ensuring that businesses remain agile in fast-paced markets.

6. Spare Parts and Repair Solutions

Another valuable solution provided by desktop 3D printers is the ability to create spare parts and repair components. In industries such as automotive and aerospace, where downtime can be costly, 3D printing allows companies to produce parts on-demand, reducing the need for large inventories of replacement parts. This is particularly useful for industries dealing with aging equipment or machinery, where certain spare parts are no longer readily available. By printing parts as needed, businesses can extend the life of their equipment and reduce repair costs, ensuring continuous operations.

7. Integration with Industry 4.0

Desktop 3D printers are also playing a critical role in the implementation of Industry 4.0, which focuses on automation, data exchange, and manufacturing technologies. These printers can be integrated with other smart devices and systems, creating a fully connected and automated production environment. This allows manufacturers to optimize workflows, monitor production processes, and make real-time adjustments, improving operational efficiency and reducing waste. The ability to combine 3D printing with other technologies like artificial intelligence and machine learning offers businesses even greater potential for innovation and efficiency.

Conclusion

The solutions provided by desktop 3D printers are reshaping the way industries approach design, manufacturing, and production. From rapid prototyping and custom manufacturing to small-batch production and educational applications, these printers offer a wide range of capabilities that cater to diverse needs. As technology continues to advance and costs continue to decrease, the impact of desktop 3D printers will only increase, offering more businesses the tools they need to innovate and stay competitive.