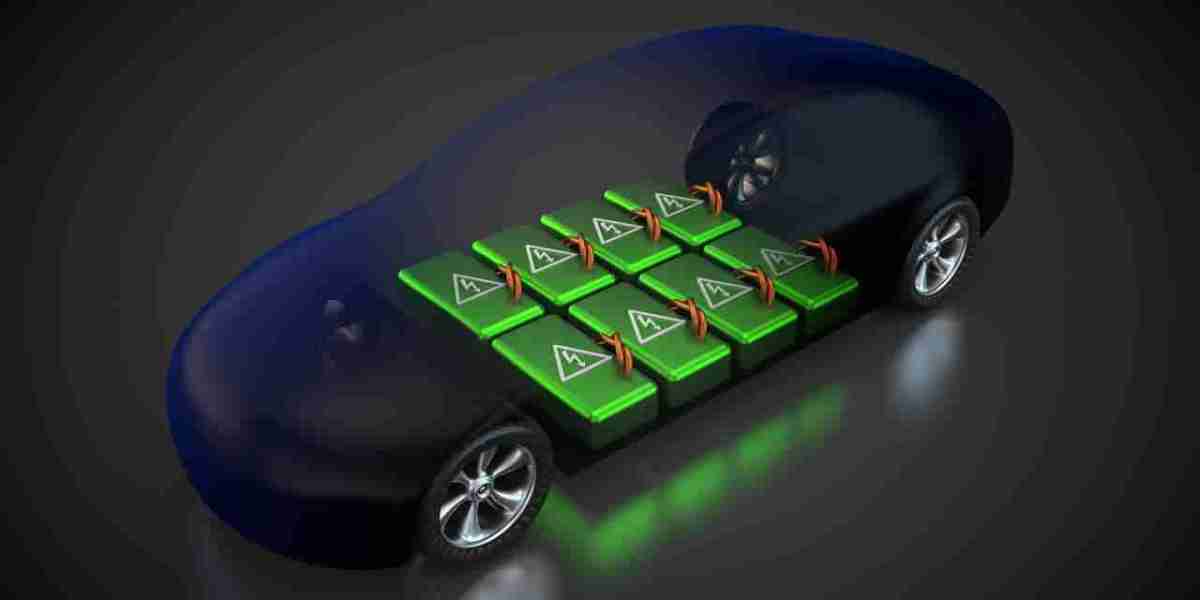

The electric vehicle battery adhesive market is growing rapidly due to increasing demand for electric vehicles (EVs) and the need for high-performance materials in battery technology. As the automotive industry shifts towards electric mobility, battery packs have become a core component of EVs. Adhesives are essential for the assembly of these battery packs, ensuring their structural integrity, thermal management, and safety. The market landscape of the electric vehicle battery adhesive sector is being shaped by numerous trends and drivers, including technological advancements, regional growth, and evolving consumer preferences.

Technological Advancements in Adhesive Materials

- Innovative formulations: Advances in adhesive technologies, such as the development of thermally conductive and flame-retardant adhesives, are driving growth in the market. These new adhesives improve the performance and safety of EV battery packs.

- Customization: Manufacturers are increasingly designing adhesives that can withstand higher temperatures and pressure, essential for new-generation battery technologies such as solid-state batteries.

- Material compatibility: Adhesives that can bond diverse materials like aluminum, plastic, and steel are gaining traction as battery components become more complex.

Rise in Electric Vehicle Production

- Surge in EV adoption: The global push towards sustainability, alongside government incentives and environmental regulations, has led to an increase in EV production. This directly impacts the demand for adhesives used in battery pack assembly.

- Growing EV portfolio: Major automakers are expanding their electric vehicle portfolios, which increases the demand for materials that enhance battery safety, durability, and efficiency.

- Demand for efficiency: Automakers are focusing on improving vehicle efficiency, which leads to a need for lightweight, compact adhesives that do not compromise on performance.

Regional Market Dynamics

- Asia-Pacific dominance: Asia-Pacific is the leading region in the electric vehicle battery adhesive market. Countries like China, Japan, and South Korea are major producers of both EVs and battery components. The large-scale production of EVs in this region continues to drive demand for adhesives.

- European market growth: Europe is witnessing rapid growth in electric vehicle production, spurred by stringent emission standards and government policies aimed at reducing carbon footprints. This region’s focus on sustainability boosts the demand for battery adhesives.

- North American developments: The North American market is growing steadily due to increased investments in EV infrastructure, government incentives, and advancements in battery technology.

Key Market Players and Collaborations

- Leading manufacturers: Companies like Henkel AG & Co., 3M, Sika AG, and H.B. Fuller are key players in the market, investing in R&D to develop advanced adhesives for battery systems.

- Strategic partnerships: To meet the increasing demand for battery adhesives, many adhesive manufacturers are collaborating with automakers and battery producers. These partnerships facilitate the development of adhesives tailored to specific battery chemistries.

- Innovation-driven competition: As more players enter the market, competition is intensifying. Companies are focusing on developing adhesives with specialized properties such as thermal conductivity, chemical resistance, and fast curing times.

Sustainability and Environmental Considerations

- Eco-friendly adhesives: Manufacturers are exploring more sustainable adhesive options as part of the broader trend towards environmentally-friendly manufacturing processes. This includes bio-based adhesives and recyclable materials.

- Regulatory pressure: The electric vehicle battery adhesive market is heavily influenced by regulations concerning product safety, chemical composition, and environmental impact. Companies are developing adhesives that meet the evolving standards set by governments around the world.

Challenges in the Market

- Cost pressures: High-performance adhesives can be expensive, which may limit their widespread adoption, especially in cost-sensitive segments of the market.

- Supply chain disruptions: The supply of key raw materials for adhesives is subject to fluctuations, affecting production timelines and costs. Manufacturers must ensure a steady supply of critical materials to meet growing demand.

- Material compatibility issues: Ensuring that adhesives are compatible with various materials used in battery cells and packs remains a significant challenge. This requires continuous research and testing to ensure optimal performance and safety.

Growth Opportunities

- Automotive sector expansion: As the automotive industry continues to embrace electric vehicles, the need for high-performance adhesives will only increase. Innovations in battery technology will create new opportunities for adhesive manufacturers.

- Battery recycling: As battery recycling technologies advance, there will be an increased focus on adhesives that allow easy disassembly of battery packs for reuse and recycling.

- New markets: As the EV market expands into developing regions, there will be new opportunities for adhesive manufacturers to cater to emerging markets where the demand for EVs is on the rise.

Conclusion

The electric vehicle battery adhesive market is set to experience robust growth as the electric vehicle industry continues to thrive. Key market drivers such as technological innovations, rising EV production, and regional demand are shaping the landscape. While challenges like cost pressures and material compatibility persist, the market is also seeing substantial opportunities for growth, particularly in new technologies, sustainability, and global market expansion.