1. Superior Electrical Conductivity

One of the most significant advantages of conductive polymer coatings is their superior electrical conductivity. Unlike traditional insulating polymers, conductive polymers are capable of conducting electricity, making them ideal for applications in electronics and electrical systems. These coatings can be used to create flexible circuits, sensors, and conductive layers in touchscreens, which are essential in the growing market for wearable electronics and flexible displays. The ability to combine the benefits of a polymer’s flexibility with electrical conductivity makes these coatings highly versatile.

Furthermore, conductive polymer coatings can be designed to have tunable conductivity, allowing them to be customized for specific applications. This flexibility in performance is one of the reasons why they are increasingly being adopted in high-tech industries.

2. Lightweight and Flexible

Conductive polymer coatings are known for their lightweight and flexible properties, which give them an edge over metal coatings in applications that require lightweight materials. For instance, in the automotive and aerospace industries, weight reduction is a critical factor for improving fuel efficiency and overall performance. Using conductive polymers as a coating material can significantly reduce the weight of parts without compromising their functionality.

Additionally, their flexibility allows them to be applied to curved or irregular surfaces, which is a key advantage in industries that require coatings for flexible electronics or soft robotics. This ability to coat flexible substrates makes conductive polymer coatings particularly useful in the emerging field of wearable devices and smart textiles.

3. Corrosion Resistance

Another major advantage of conductive polymer coatings is their corrosion resistance. Traditional metal coatings are prone to rust and degradation over time, especially in harsh environments exposed to moisture, heat, or chemicals. However, conductive polymers provide an excellent protective layer that resists corrosion and extends the lifespan of components.

This property is especially valuable in electronics and automotive industries, where parts must withstand extreme environmental conditions. For example, electrical connectors and circuit boards are often exposed to moisture, but the use of conductive polymer coatings helps protect these components from corrosion, ensuring better performance and reliability over time.

4. Environmental Benefits

As the world moves toward greener technologies, conductive polymer coatings offer significant environmental benefits. These coatings can be manufactured using renewable, bio-based materials, which reduces the reliance on petroleum-based products. Additionally, conductive polymers are recyclable and can be processed with fewer harmful solvents compared to traditional coatings, making them a more environmentally friendly alternative.

Moreover, many conductive polymers have the potential to be biodegradable, offering a sustainable option for the electronics industry, which generates substantial waste. By incorporating conductive polymer coatings, manufacturers can contribute to reducing the environmental impact of electronic waste, promoting a circular economy.

5. Cost-Effectiveness

Conductive polymer coatings are often more cost-effective than traditional metal coatings. The production process for conductive polymers generally requires lower energy consumption, reducing manufacturing costs. Additionally, these coatings can be applied in a thin layer, reducing material usage and waste. This makes them more affordable for manufacturers, especially in industries where cost efficiency is crucial.

The processing techniques for conductive polymer coatings, such as spray coating and screen printing, are less complex and require less specialized equipment compared to metal-based coatings, further reducing overall production costs. This makes conductive polymer coatings a viable option for large-scale manufacturing, especially for industries seeking to balance performance and affordability.

6. Durability and Long-Lasting Performance

Conductive polymer coatings are also known for their durability and long-lasting performance. These coatings provide excellent protection against mechanical wear, abrasion, and environmental degradation. This means that components coated with conductive polymers can maintain their electrical conductivity and protective properties for extended periods, even under challenging conditions.

In industries such as automotive and aerospace, where long-term reliability is crucial, the use of conductive polymer coatings ensures that components will perform optimally throughout their lifespan, reducing the need for maintenance and replacements. This durability enhances the overall cost-effectiveness and sustainability of using conductive polymer coatings in various applications.

7. Versatility in Applications

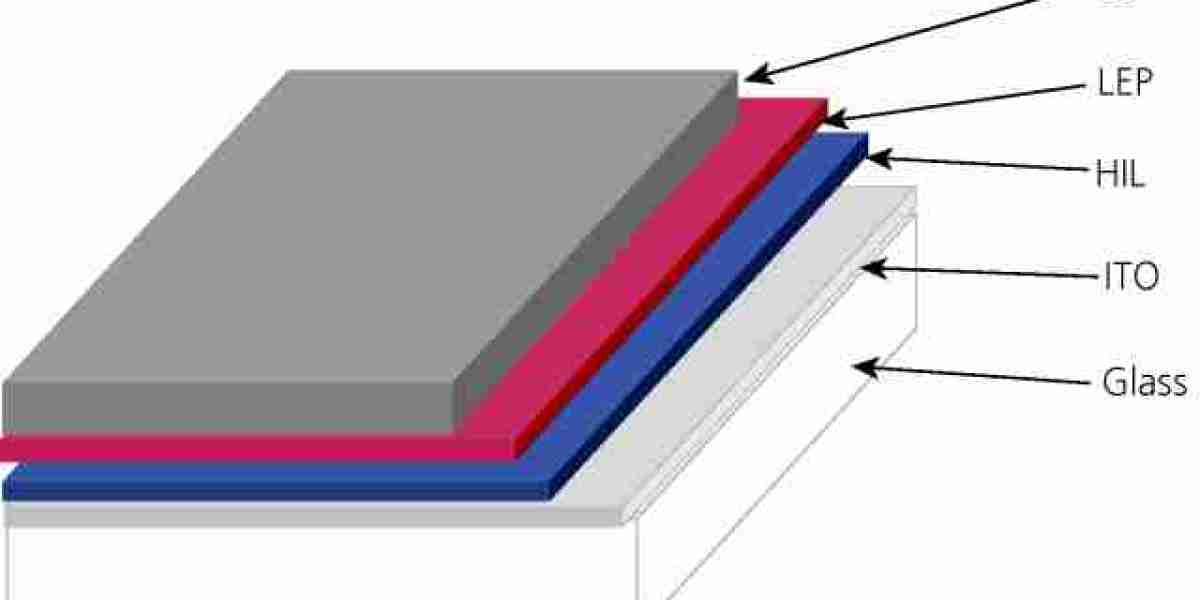

The versatility of conductive polymer coatings is one of their most significant advantages. These coatings can be used in a wide variety of industries and applications, including electronics, automotive, aerospace, healthcare, and renewable energy. They can be applied to different substrates, such as plastics, glass, metals, and ceramics, expanding their potential uses.

In the electronics industry, conductive polymer coatings are essential for creating flexible displays, touchscreens, and smart sensors. In the automotive sector, they are used to create lightweight, corrosion-resistant parts, while in the healthcare industry, conductive polymers are employed in biosensors and wearable health devices. The potential applications are vast, and the flexibility of conductive polymer coatings makes them highly adaptable to emerging technologies.

Conclusion

The conductive polymer coating market is poised for continued growth due to the significant advantages these materials offer. Their electrical conductivity, lightweight flexibility, corrosion resistance, environmental benefits, cost-effectiveness, and durability make them ideal for a wide range of applications. As industries continue to seek more sustainable and efficient materials, conductive polymer coatings will play a key role in shaping the future of technology, driving innovation across sectors from electronics to aerospace. With their numerous benefits, these coatings are likely to become an essential material in the modern materials science landscape.