Fuel efficiency is a top priority in the automotive industry. With the growing desire to reduce our carbon footprint, automotive body parts manufacturers continually seek ways to make vehicles more fuel-efficient. Hence, many manufacturers pursue the use of lightweight materials.

Why Weight Matters

It's simple physics—less weight requires less energy to move, resulting in improved fuel efficiency. With the increasing emphasis on reducing greenhouse gas emissions and improving air quality, the weight of a vehicle plays a pivotal role.

Moreover, the weight of a vehicle impacts not only fuel efficiency but also emissions. You probably know that heavier vehicles typically emit more pollutants.

The Transition to Lightweight Materials

In the early days of automotive manufacturing, steel reigned supreme as the primary material for constructing car bodies. While steel is durable and strong, it is also heavy. But, many carmakers want to balance safety, strength, and weight reduction. It led to a shift in the industry towards lightweight materials.

Lightweight Materials in Action

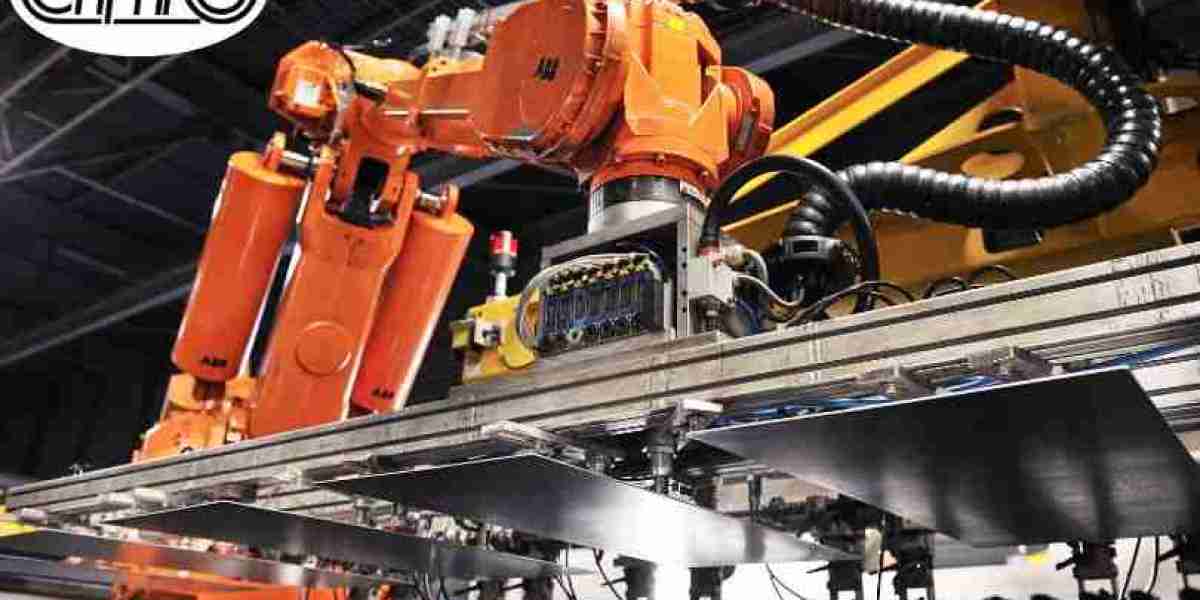

You must know that aluminum has emerged as a game-changer in the automotive manufacturing landscape. Its exceptional strength-to-weight ratio has allowed automotive body parts manufacturers to produce lighter vehicles without compromising structural integrity. The adoption of aluminum in body panels and structures has significantly contributed to improved fuel efficiency.

Most manufacturers know carbon fiber for its exceptional strength and lightweight properties. It is an essential player in the automotive industry. This versatile material finds applications in various aspects, from crafting lightweight body panels to contributing to the construction of entire car bodies.

Furthermore, the door assembly parts manufacturer also utilizes carbon fiber. It adds to the comprehensive use of carbon fiber in enhancing the structural integrity and overall performance of modern vehicles.

Conclusion

The undeniable significance of lightweight materials has ushered in an era of eco-friendly and economically efficient vehicles. Companies like Caparo, known for their expertise in materials and manufacturing, continue to push the boundaries of innovation in this field. As the automotive industry evolves, the role of lightweight materials, including those used by a door assembly parts manufacturer, remains pivotal in shaping the vehicles of the future.