Introduction to Jigs and Fixtures

In manufacturing, precision and efficiency are critical for producing high-quality products. To achieve these goals, tools like jigs and fixtures are employed to ensure parts are held securely and positioned accurately during machining processes. These specialized devices are essential for mass production, enhancing both accuracy and repeatability while reducing setup time. In this article, we will explore the importance of jigs and fixtures, their differences, types, applications, and how they contribute to modern manufacturing.

What Are Jigs and Fixtures?

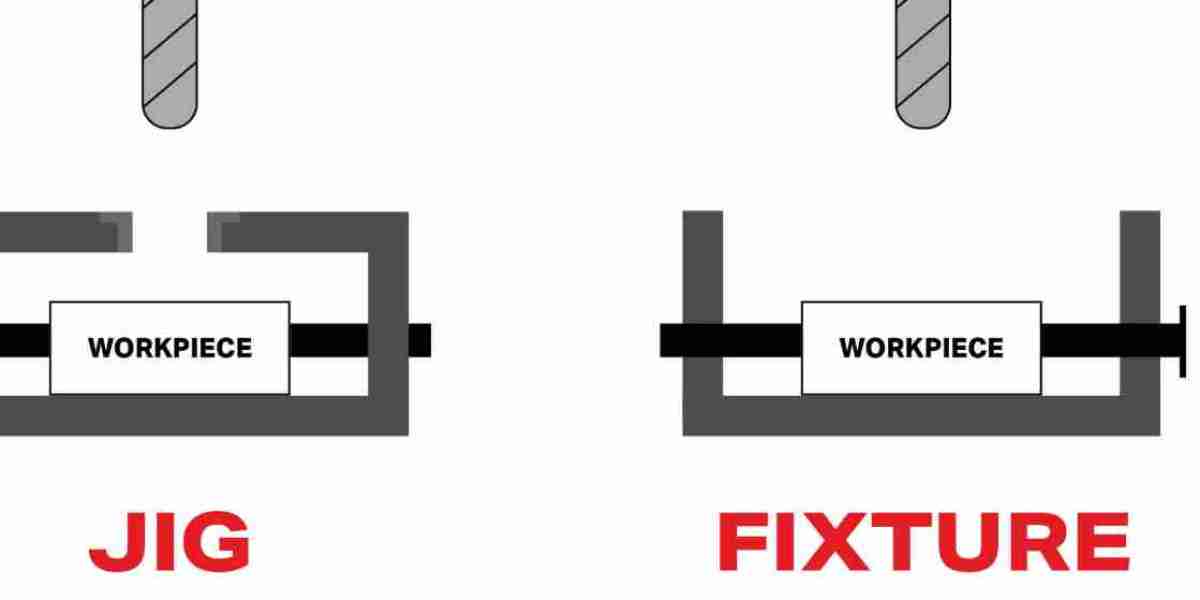

Jigs and fixtures are tools used in manufacturing processes to hold and support workpieces securely, ensuring precise and accurate machining operations. Although they are often used interchangeably, jigs and fixtures have distinct functions.

- Jigs: A jig is a tool that holds the workpiece in place and guides the cutting tool. It helps ensure that the tool follows a specific path or maintains a certain angle, improving precision. Jigs are often used in operations like drilling, reaming, and tapping.

- Fixtures: A fixture is a tool used to hold and support the workpiece during machining but does not guide the cutting tool. Fixtures are designed to keep the workpiece steady in one position while a machine tool, such as a mill or lathe, performs the necessary cutting operations.

While both jigs and fixtures are designed to enhance the accuracy and efficiency of machining processes, their roles differ in terms of their functionality.

Key Differences Between Jigs and Fixtures

While jigs and fixtures are both essential for precision in manufacturing, they serve different purposes. Here are the key differences between them:

| Feature | Jigs | Fixtures |

|---|---|---|

| Function | Guides the cutting tool | Holds the workpiece in place |

| Primary Use | Drilling, reaming, and tapping | Milling, turning, grinding |

| Tool Guidance | Guides the tool’s movement | Does not guide the tool movement |

| Complexity | More complex, often movable | Simpler design |

| Application | Used for small or intricate parts | Used for larger, bulkier workpieces |

| Adjustability | Adjustable for various sizes | Typically designed for specific workpieces |

Types of Jigs and Fixtures

There are several types of jigs and fixtures used in different manufacturing processes. Each type is tailored to improve specific operations, whether it’s drilling, milling, or turning. Let’s take a closer look at some of the most common types.

Types of Jigs

Drill Jigs: These are used in drilling operations to ensure that holes are drilled at precise locations and angles. Drill jigs typically include guides that help position the drill bit accurately.

- Application: Used in mass production where drilling multiple holes in identical workpieces is required.

- Example: In automobile manufacturing, drill jigs are used to drill holes in car body panels for fastening.

Bushing Jigs: Bushing jigs are used to hold the workpiece in place and guide the drill bit. They are equipped with replaceable bushings that provide additional support and allow for quick tool changes.

- Application: Common in the automotive and aerospace industries where precision drilling is required.

- Example: Bushing jigs are used in the assembly of complex components like engine parts and frames.

Template Jigs: Template jigs use a template to guide the cutting tool in specific patterns. They are simple and cost-effective tools used for precision cutting in woodworking and metalworking.

- Application: Often used in the production of parts with repeated, complex shapes.

- Example: Woodworking industries use template jigs for creating intricate designs and patterns on furniture.

Types of Fixtures

Milling Fixtures: These are used in milling operations to secure the workpiece while the milling machine performs cutting tasks. They are designed to provide stability and minimize movement during the milling process.

- Application: Used for cutting, grinding, or shaping large workpieces.

- Example: Milling fixtures are commonly used in industries such as automotive, aerospace, and machine tool manufacturing.

Lathe Fixtures: Lathe fixtures hold workpieces firmly during turning operations, ensuring that they remain stationary as the tool performs rotary cutting.

- Application: Primarily used in turning operations, including threading, tapering, and shaping.

- Example: Lathe fixtures are commonly used for cylindrical parts, such as shafts or spindles, in industries like automotive manufacturing.

Grinding Fixtures: These fixtures hold workpieces steady during grinding processes. They are designed to prevent movement and ensure accurate grinding for smooth finishes.

- Application: Used for high-precision grinding operations that require fine tolerances.

- Example: Grinding fixtures are used in tool and die making, as well as in the manufacturing of medical devices and industrial components.

Welding Fixtures: These fixtures are used to hold workpieces in place during the welding process. They ensure that components are aligned properly for accurate welding and prevent distortion due to heat.

- Application: Used in industries such as construction, automotive, and aerospace.

- Example: Welding fixtures are commonly used in the assembly of vehicle frames and heavy machinery.

Benefits of Jigs and Fixtures in Manufacturing

The use of jigs and fixtures offers several benefits in the manufacturing process, including:

Improved Accuracy: Jigs and fixtures ensure that the workpiece is positioned correctly, resulting in more accurate machining operations. This reduces the chances of errors and ensures parts are made to the correct specifications.

Increased Efficiency: Jigs and fixtures reduce setup time and increase the speed of machining processes, allowing for more parts to be produced in less time. This leads to improved productivity, especially in mass production environments.

Enhanced Repeatability: Once a jig or fixture is set up, it can be used to produce multiple identical parts with the same level of accuracy. This repeatability is essential in industries where consistency is key.

Cost-Effectiveness: While the initial cost of jigs and fixtures can be high, they save money in the long run by reducing the need for skilled labor, improving part accuracy, and decreasing scrap rates.

Reduced Human Error: By guiding the cutting tool or holding the workpiece securely, jigs and fixtures minimize human error and increase the overall reliability of the manufacturing process.

Applications of Jigs and Fixtures

Jigs and fixtures find applications across a variety of industries, including:

Automotive Industry: Jigs and fixtures are used extensively in automotive manufacturing for tasks like drilling, milling, and welding. They ensure that parts such as engine blocks, transmission housings, and body panels are manufactured with high precision and efficiency.

Aerospace Industry: The aerospace industry relies on jigs and fixtures for high-precision manufacturing of critical components like turbine blades, aircraft frames, and fuselage parts. These fixtures ensure that parts meet stringent quality and safety standards.

Construction: In construction, jigs and fixtures are used for the fabrication of structural components, including beams, girders, and columns. Welding fixtures are particularly important for ensuring proper alignment during the welding process.

Consumer Electronics: Jigs and fixtures are used in the mass production of electronic components such as circuit boards, casings, and assembly parts. They help maintain high levels of accuracy and reduce defects in the production process.

Conclusion

Jigs and fixtures are fundamental tools in modern manufacturing, enabling businesses to produce high-quality products with precision, speed, and efficiency. Whether used in drilling, milling, turning, or welding, these tools play a vital role in optimizing production processes. By understanding the types, benefits, and applications of jigs and fixtures, manufacturers can make informed decisions that enhance their operations, reduce costs, and improve product consistency. As industries continue to evolve, the demand for innovative and high-performing jigs and fixtures will only increase, driving further advancements in manufacturing technology.