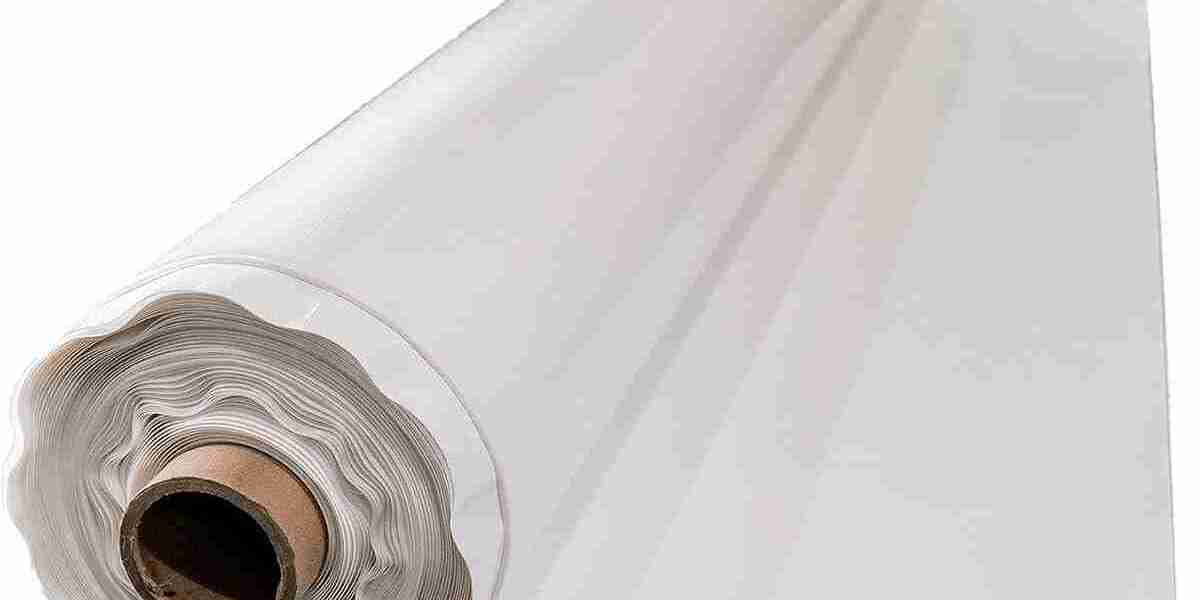

The vapor barrier films market is undergoing significant transformations, driven by several key factors that are reshaping industries worldwide. As demand for energy-efficient building materials, sustainable packaging, and effective moisture control grows, the market for vapor barrier films is positioned for robust expansion. This research dives into the key drivers, restraints, and strategic insights that will influence the growth trajectory of the market in the coming years.

Key Drivers of the Vapor Barrier Films Market

One of the primary drivers of the vapor barrier films market is the growing demand for energy-efficient and eco-friendly construction materials. In today’s construction sector, there is a heightened focus on sustainability, particularly with the introduction of green building certifications and energy-saving regulations. Vapor barrier films play a crucial role in preventing moisture infiltration in buildings, improving insulation, and reducing energy consumption by maintaining a controlled internal environment. As the global demand for energy-efficient buildings continues to rise, vapor barrier films have become a key component of modern construction, contributing to the expansion of the market.

Technological advancements also serve as a major driver. Over the past few years, manufacturers have introduced high-performance vapor barrier films made from advanced polymers such as polyethylene and polyamide. These materials are more resistant to moisture, UV radiation, and extreme temperatures, making them highly effective in safeguarding goods. In addition, the use of nanotechnology and multi-layered films has improved the strength and flexibility of vapor barriers, while maintaining their lightweight nature. The ongoing research and development efforts aimed at enhancing the durability and functionality of these films are likely to keep driving the market forward.

Furthermore, the increased awareness of the risks posed by moisture damage in packaging and agricultural sectors has led to greater adoption of vapor barrier films. In packaging, these films help extend the shelf life of perishable products, preventing spoilage due to moisture exposure. Similarly, in agriculture, vapor barrier films are used to maintain optimal humidity levels and ensure the safe storage of crops, particularly in regions with fluctuating climate conditions.

Restraints in the Vapor Barrier Films Market

Despite the promising growth, the vapor barrier films market faces several challenges. One of the primary restraints is the high production cost associated with advanced vapor barrier films. Materials like polyethylene, while effective, are expensive to produce when combined with enhanced properties such as high moisture resistance, UV protection, and multi-layered designs. This increases the overall cost of vapor barrier films, making them less affordable, particularly for price-sensitive markets.

Additionally, the market faces intense competition from alternative moisture protection solutions, such as liquid-applied barriers and coatings. While vapor barrier films are highly effective, liquid barriers and coatings offer flexibility and ease of application, especially in areas with complex geometries. As a result, companies in the vapor barrier films market must continue to innovate to maintain a competitive edge and address the challenges posed by these alternative solutions.

Strategic Insights for Future Growth

To overcome these challenges and capitalize on emerging opportunities, companies in the vapor barrier films market must focus on several strategic approaches. First, investment in research and development (R&D) is essential for enhancing product quality, reducing production costs, and developing new solutions. By exploring sustainable and biodegradable materials, manufacturers can align their products with the growing demand for environmentally friendly solutions, giving them an edge in the market.

Regional expansion also offers significant growth potential. Emerging economies, particularly in Asia-Pacific, present lucrative opportunities due to rapid urbanization, infrastructural development, and an increasing awareness of sustainable building practices. Companies should focus on establishing a strong presence in these regions through partnerships, local manufacturing, and targeted marketing.

Moreover, collaboration with the construction, packaging, and agriculture sectors can provide opportunities to develop tailored solutions for specific applications. Customized vapor barrier films designed to meet the unique needs of these industries will help manufacturers differentiate their offerings and capture new market segments.

Conclusion

The vapor barrier films market is poised for continued growth, driven by key drivers such as the rising demand for energy-efficient construction, technological advancements, and the need for moisture control in agriculture and packaging. However, challenges such as high production costs and competition from alternative solutions remain. By focusing on innovation, regional expansion, and partnerships with end-use industries, companies can leverage the opportunities presented by the growing demand for moisture protection and energy-efficient materials. The future of the vapor barrier films market looks promising, with continued technological advancements and evolving consumer demands shaping its success.