The force sensors market is evolving with significant advancements in material technologies. As industries demand more accurate, durable, and efficient sensors, material innovations are playing a key role in meeting these needs. New materials are enabling the development of sensors that are not only more precise but also more adaptable to a range of challenging environments, from automotive to healthcare.

Key Material Developments Driving Force Sensors Innovation

1. Advanced Composites for Durability

The use of advanced composite materials is significantly enhancing the durability and performance of force sensors. These composites offer a combination of strength, flexibility, and resistance to wear and tear, making them ideal for harsh environments. In industrial applications, where sensors are subjected to extreme pressure and temperature fluctuations, composites provide increased lifespan and reliability.

2. Smart Materials for Enhanced Sensitivity

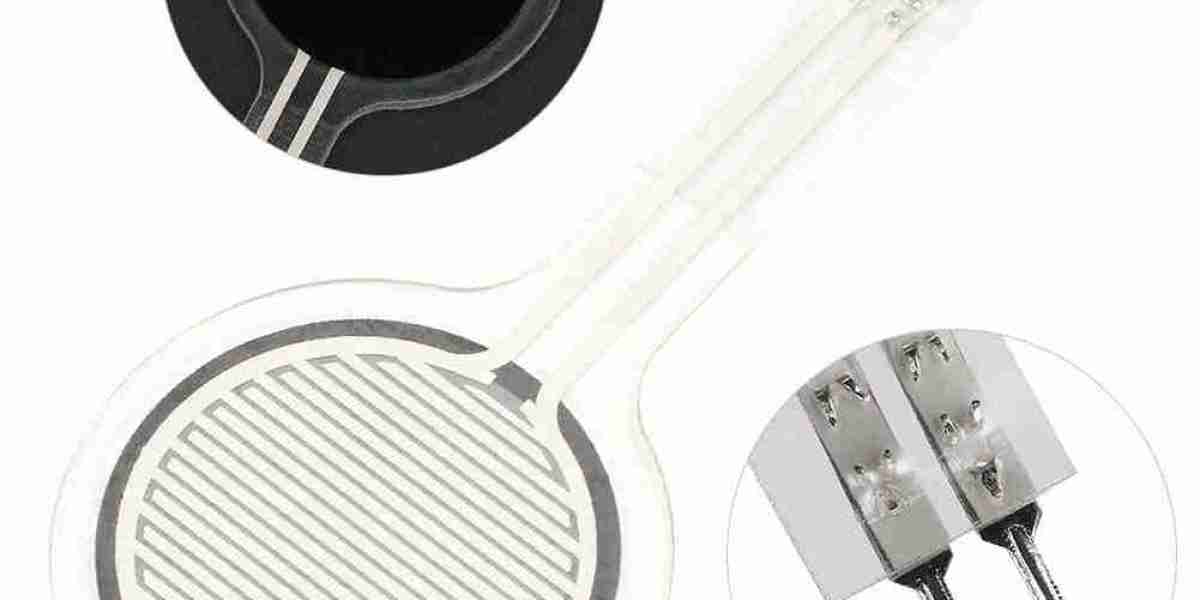

Smart materials, such as piezoelectric and shape-memory alloys, are transforming force sensor performance. These materials respond to mechanical stress by generating electrical signals, allowing for precise measurements of force, pressure, or strain. Their ability to change shape in response to environmental changes makes them highly valuable in applications requiring high sensitivity, such as robotics, medical devices, and aerospace.

3. Silicon-Based Sensors

Silicon-based materials are a cornerstone in the development of microelectromechanical systems (MEMS) for force sensors. MEMS technology allows for the miniaturization of sensors while maintaining accuracy and sensitivity. Silicon’s ability to integrate with other semiconductor technologies is making it an ideal material for developing compact, high-performance sensors used in automotive, consumer electronics, and wearable devices.

4. Carbon Nanotubes and Graphene

Carbon nanotubes (CNTs) and graphene are emerging as groundbreaking materials in force sensor design due to their exceptional strength, conductivity, and flexibility. CNTs and graphene-based sensors can measure forces with high precision, even at microscopic scales, and are especially useful in biomedical applications. Their use in wearable technology, flexible electronics, and high-performance sensors is expanding rapidly as industries seek more advanced materials for next-generation devices.

5. Conductive Polymers for Flexibility

Conductive polymers offer a unique combination of flexibility, lightweight design, and electrical conductivity, making them highly suitable for force sensors that need to be integrated into flexible and stretchable electronics. These materials are widely used in the development of sensors for wearable technology, soft robotics, and flexible displays. The ability to stretch and conform to different shapes while maintaining accurate force measurement makes conductive polymers indispensable in emerging applications.

Impact of Material Innovations on Force Sensor Applications

Healthcare: Advanced materials are enabling the creation of more sensitive and reliable force sensors for medical devices. In robotic surgery, for instance, piezoelectric sensors provide real-time tactile feedback, improving precision. Smart materials also support the development of wearable health-monitoring devices, allowing for non-invasive monitoring of vital signs.

Automotive and Aerospace: The demand for lightweight yet durable sensors in automotive and aerospace applications has led to the adoption of composite materials. These materials enhance the sensor's ability to withstand vibrations, extreme temperatures, and pressures, ensuring optimal performance in vehicles and aircraft.

Consumer Electronics: The integration of silicon-based sensors and flexible conductive polymers in consumer electronics has led to the creation of ultra-compact, high-performance devices. Wearable sensors, touch screens, and haptic feedback systems in smart gadgets rely on these material innovations to deliver precision and efficiency.

Industrial Automation: The increasing adoption of robotics and automation in manufacturing has driven demand for force sensors made from durable composites and smart materials. These sensors are critical in controlling robotic movements, providing feedback on force, pressure, and torque to improve productivity and reduce the risk of errors.

Challenges and Opportunities in Material Innovations

Challenges

Cost and Production Scalability: Advanced materials like graphene and carbon nanotubes are often expensive to produce at scale. This can limit their widespread adoption, particularly in industries with tight budgets or cost-sensitive applications.

Material Compatibility: Integrating new materials with existing sensor technologies can present challenges. Ensuring that advanced materials work seamlessly with established manufacturing processes and electronic systems is a complex task.

Sustainability Concerns: Some advanced materials, particularly those used in MEMS and composite sensors, may pose environmental challenges during disposal. Developing sustainable materials that do not harm the environment is crucial for the future growth of the force sensor market.

Opportunities

Emerging Applications: As industries seek to develop more advanced, compact, and efficient devices, there is a significant opportunity for new materials to support the next generation of force sensors. Applications in flexible electronics, smart wearables, and soft robotics are expanding, and new materials will be at the forefront of this growth.

Collaboration and Research: Material science research and development are rapidly advancing, with new innovations continuously emerging. Collaboration between sensor manufacturers and material scientists offers immense opportunities to unlock new possibilities in sensor performance and functionality.

Final Thoughts

Material developments are shaping the future of the force sensors market by enabling the creation of sensors that are more durable, sensitive, and adaptable to a variety of industries. Innovations in smart materials, composites, and nanotechnology are opening up new possibilities for applications in healthcare, automotive, aerospace, and industrial automation. As the demand for more advanced sensors grows, material innovations will continue to play a critical role in advancing the capabilities and efficiency of force sensors.