The tray sealing machines market is experiencing transformative changes, largely driven by evolving consumer preferences and the increasing demand for convenience, sustainability, and food safety. Tray sealing technology, which is used to package a wide variety of products ranging from fresh food to pharmaceuticals, is at the forefront of these changes. As consumers become more conscious of the impact of packaging on the environment, health, and convenience, manufacturers are adapting their packaging solutions to meet these shifting demands. The trend is pushing companies to innovate, with tray sealing machines playing a critical role in shaping how products are presented, preserved, and delivered.

Market Overview: The Impact of Consumer Preferences on Tray Sealing

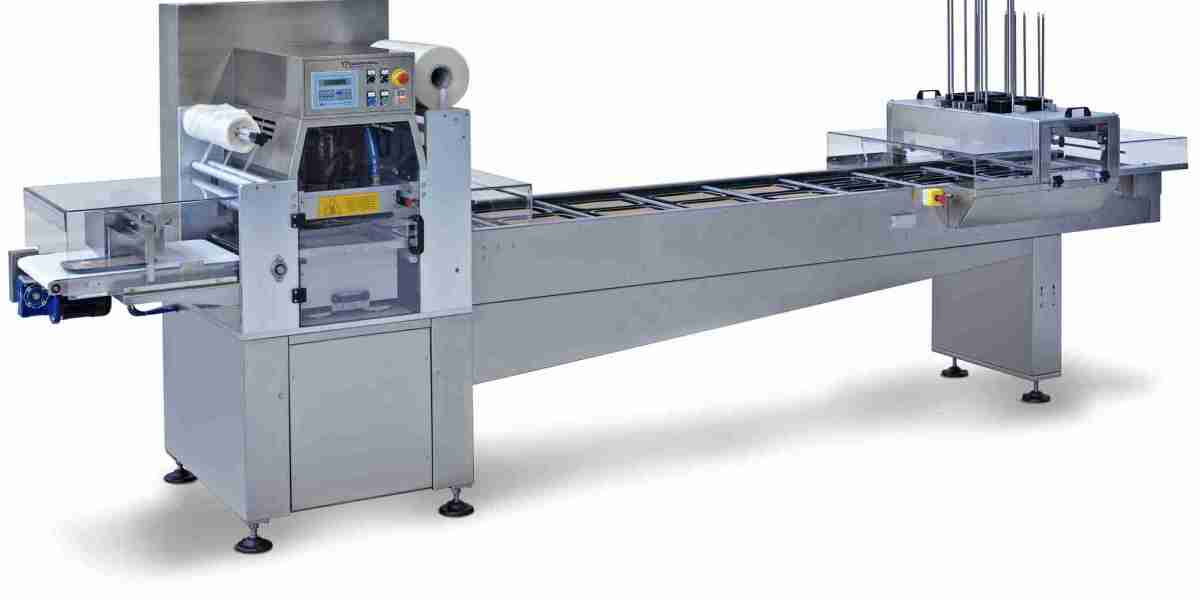

Tray sealing machines are primarily used to seal products into protective trays, which are then sealed with a variety of films to ensure product safety and quality. This technology is employed across several industries, most notably in the food sector. As consumer expectations evolve, there is an increasing emphasis on packaging that offers not only functionality but also convenience, freshness, and sustainability.

The most significant change within the tray sealing machines market has been the shift in consumer preferences toward environmentally friendly packaging. As awareness of plastic waste and its environmental consequences grows, consumers are pushing brands to adopt more sustainable practices. This demand has prompted food manufacturers and other industries to invest in packaging that is not only effective in preserving the product but also more eco-conscious. Tray sealing machines are being upgraded to accommodate recyclable, compostable, or biodegradable materials, responding to consumer calls for reduced reliance on single-use plastics.

Sustainability: A Key Driver of Change

Sustainability has become a central theme in the tray sealing machines market. Consumers are increasingly aware of the environmental impact of packaging materials, especially plastics, and are seeking products with packaging that reflects their values. This shift is impacting how companies approach product packaging, with many opting for sustainable alternatives like plant-based films or materials that can be easily recycled. As a result, tray sealing machines must be capable of working with these new materials, driving manufacturers to design machines that can handle a variety of substrates without compromising on the integrity of the seal or the quality of the product.

Convenience and Freshness: Meeting the Demand for Ready-to-Eat Foods

In addition to sustainability, consumer preferences for convenience are significantly shaping packaging designs. As busy lifestyles continue to drive the demand for ready-to-eat meals and pre-packaged snacks, packaging that offers convenience is increasingly important. Tray sealing technology is particularly suited for this shift, as it enables manufacturers to create portion-controlled, easy-to-open packaging that preserves freshness for longer periods.

Consumers are looking for packaging that can offer convenience without compromising the quality of the food. Modified atmosphere packaging (MAP), a feature of many tray sealing machines, is a great example of how the packaging process is evolving to meet consumer demand. MAP extends the shelf life of fresh foods by adjusting the gases inside the sealed tray, which helps maintain the product's flavor, texture, and nutritional content. This is especially important in the ready-to-eat and fresh produce sectors, where freshness is a top priority.

Tray sealing machines are also evolving to meet the demand for packaging that is user-friendly. Packaging designs that are easy to open, reseal, and dispose of are becoming increasingly important, particularly in the consumer goods sector. As more consumers seek products that offer hassle-free usage, manufacturers are incorporating features like peelable seals or easy-tear films into their tray sealing machines, enhancing the overall consumer experience.

Personalization: Custom Packaging Solutions

Personalization is another trend shaping the packaging industry. As brands strive to connect with consumers on a deeper level, many are turning to customized packaging that reflects their unique identity or appeals to specific consumer segments. Tray sealing machines are adapting to this trend by providing the ability to create custom-sized trays, different shapes, and bespoke branding opportunities.

For example, in the food sector, some companies are using custom packaging to highlight the premium nature of their products or to appeal to health-conscious consumers. In pharmaceuticals, personalized packaging solutions can cater to specific treatment needs, such as packaging that reflects the specific dosage or administration instructions for a drug. This trend toward customization is forcing manufacturers of tray sealing machines to offer more flexible solutions that can accommodate a wide range of sizes, designs, and materials.

Market Forecast: Growth and Innovation in the Tray Sealing Machines Market

The forecast for the tray sealing machines market is positive, with growth expected across several sectors driven by the continued shift in consumer preferences. The increasing demand for sustainable packaging, convenience, and customization are likely to remain key drivers of this market. Additionally, innovations in automation and smart technology will further enhance the capabilities of tray sealing machines, offering manufacturers the opportunity to improve production efficiency, reduce waste, and meet the increasingly complex demands of the market.