The conductive polymer coating market has been growing rapidly in recent years, thanks to its broad applications in industries such as automotive, electronics, energy storage, and consumer goods. However, despite the promising prospects, the market faces a number of growth challenges that could hinder its expansion in the long term. These challenges, ranging from technological limitations to regulatory hurdles, must be addressed to unlock the full potential of conductive polymer coatings.

1. Technological Limitations

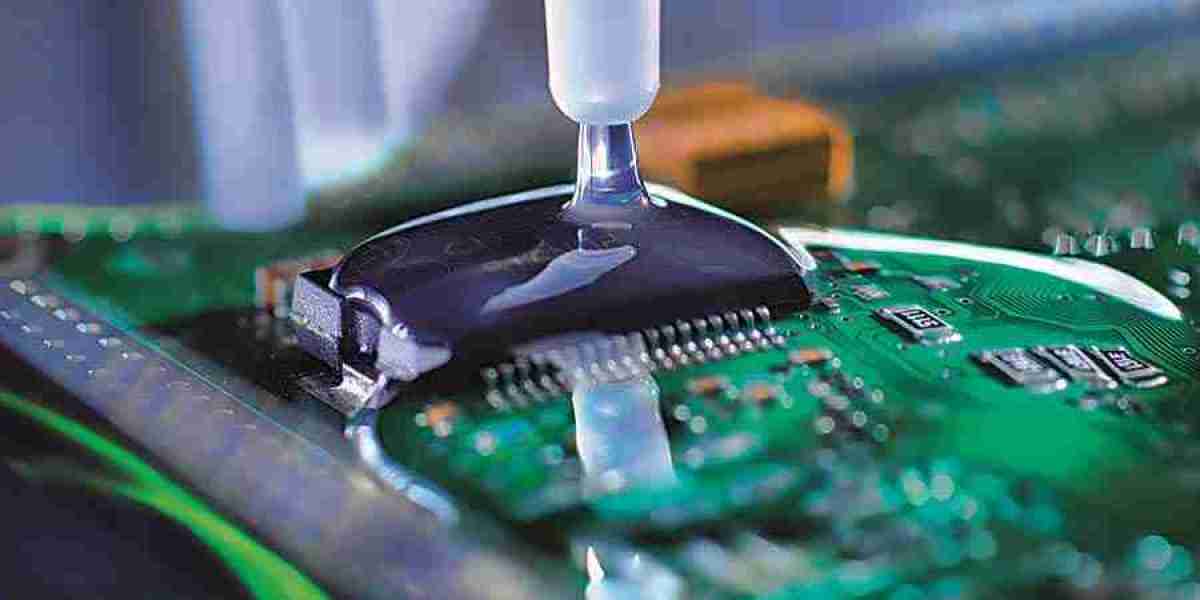

One of the primary challenges limiting the growth of the conductive polymer coating market is the technological limitations of the materials themselves. While conductive polymers are widely used for their excellent electrical conductivity, they often face challenges in terms of their mechanical properties, such as strength, durability, and long-term stability. In many applications, the mechanical properties of conductive polymers may not meet the stringent performance requirements, limiting their adoption in high-performance industries like aerospace or high-end electronics.

The development of more robust conductive polymers, including those with enhanced thermal stability, flexibility, and mechanical strength, is essential to overcoming this challenge. Continued advancements in material science are critical to improving the overall functionality of conductive polymer coatings and expanding their range of applications.

2. Cost Constraints

Despite the growing demand for conductive polymers, their high production costs remain a significant barrier to widespread adoption. The manufacturing of high-quality conductive polymer coatings involves complex processes, including the use of expensive raw materials and specialized equipment. This results in a higher cost of production compared to conventional coatings, making it difficult for manufacturers to offer these products at competitive prices.

For smaller companies or those operating in regions with lower production budgets, this cost discrepancy can be a major deterrent. To overcome this challenge, manufacturers need to invest in research and development (R&D) to develop cost-effective production methods, such as the use of low-cost raw materials or improved manufacturing processes that reduce energy consumption.

3. Regulatory Challenges

The conductive polymer coating industry is also impacted by regulatory frameworks in different regions. The use of these coatings in certain industries, such as electronics and energy storage, is often governed by strict standards and regulations, especially regarding safety, environmental impact, and product certifications. For example, the chemical composition of conductive polymers must adhere to regulations on the use of hazardous materials in electronic devices.

The regulatory landscape varies from region to region, and manufacturers must ensure compliance with international standards, which can be a complex and time-consuming process. In addition, as the market grows, more stringent environmental and safety regulations are likely to be implemented, which could increase the cost and time involved in product development and testing.

4. Limited Consumer Awareness

Another obstacle to growth is the limited awareness of conductive polymer coatings among potential customers. While conductive polymers are increasingly used in specialized industries, many businesses are still unaware of the benefits these coatings offer. This lack of awareness often leads to slower adoption rates, as companies may continue to rely on traditional coating technologies that are familiar to them.

Efforts to educate the market about the advantages of conductive polymer coatings, such as improved conductivity, corrosion resistance, and environmental sustainability, are crucial to overcoming this challenge. Companies in the sector must engage in marketing campaigns, educational seminars, and product demonstrations to increase awareness and drive demand.

5. Competition from Alternative Coatings

The market for coatings is highly competitive, with numerous alternatives available to businesses seeking coating solutions. Traditional coatings, such as metallic coatings, carbon-based coatings, and other conductive materials, continue to be popular options in various industries. These alternatives, though not always as effective as conductive polymers in specific applications, may be more cost-efficient or readily available.

The challenge for the conductive polymer coating market lies in differentiating its products from these alternatives. Manufacturers must highlight the unique advantages of conductive polymers, such as their lightweight nature, corrosion resistance, and potential for customization. Innovation in product design and the ability to deliver superior performance will be key to maintaining competitiveness in the market.

6. Supply Chain Disruptions

Global supply chain disruptions, especially in light of recent events like the COVID-19 pandemic, have also impacted the conductive polymer coating market. The raw materials required for the production of these coatings, such as specific polymers and additives, are often sourced from different parts of the world. Disruptions in the supply of these materials can lead to delays in production and increased prices.

To mitigate this issue, companies must invest in building more resilient and diversified supply chains. This could include sourcing raw materials from multiple suppliers or exploring alternative materials that can be used to create conductive coatings.

Conclusion

The conductive polymer coating market holds significant promise, but several growth challenges must be addressed to unlock its full potential. Overcoming technological limitations, managing costs, adhering to regulatory frameworks, raising consumer awareness, and differentiating from competitors will be essential to the long-term success of the market. By investing in research, innovation, and strategic partnerships, manufacturers can overcome these challenges and position themselves for continued growth in the dynamic and evolving coatings industry.