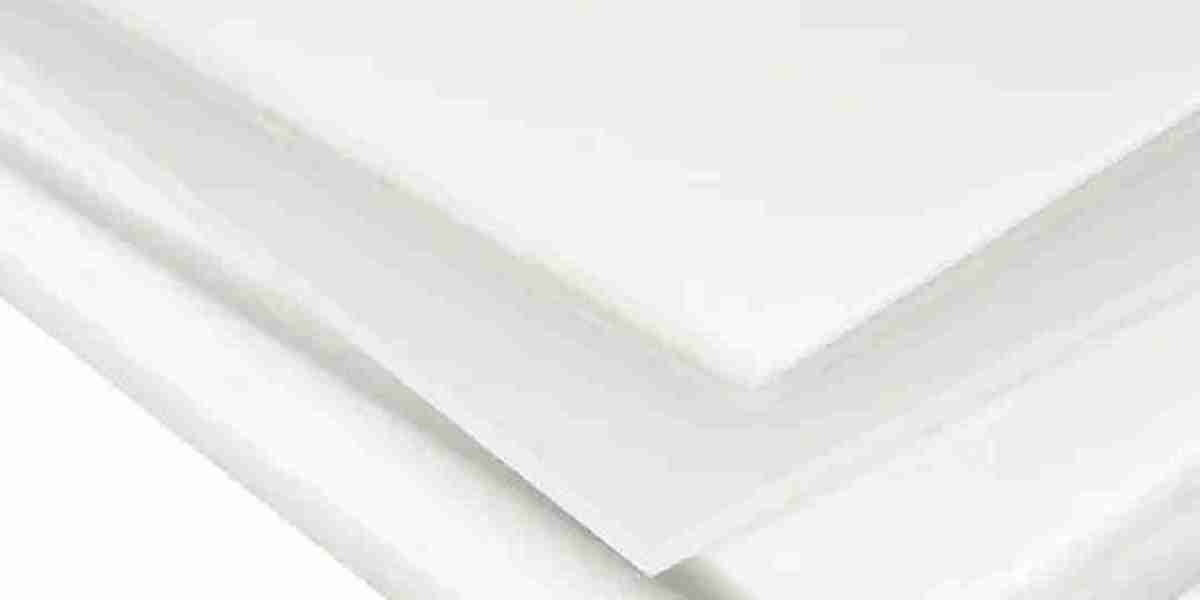

Today, in the countless polymer available, polypropropylene (PP) stands as a real work heifer, and its sheet form, PP sheets, has become an indispensable component of countless industries. For complex engineering miracles ranging from strong packaging solutions, the humble PP sheet offers a unique mixture of properties that make it designers, engineers and manufacturers create materials for reliable, cost -effective and optimal solutions. The low density, chemical resistance, excellent life and remarkable versatility make it a quiet master based on our modern lives.

The Genesis and Evolution of Polypropylene

To appreciate the PP sheet manufacturer in Pune one must first understand its basic content: polypropylene. Polypropylene was detected in the mid -1900s and gained rapid traction due to her attractive properties. It is a thermoplastic polymer, which means it can be melted and improved several times without significant decline, making it excessive recycling and thus environmentally friendly. Unlike any other plastic, polypropylene is known for relatively simple molecular structure, which contributes to easy processing and cost efficiency. For decades, the progress of polymerization techniques and additive techniques has further enhanced the properties of polypropylene, leading to a diverse range of customized characters for specific applications. This continuous growth has strengthened its position as one of the most widely used plastics globally, the PP sheet appears to be a particularly important application form.

Unpacking the Properties of PP Sheet

The popularity of PP sheets dates from the extraordinary selection of direct properties. One of the main benefits is its low density, making it a mild alternative for many other materials. This is important for applications where weight loss is crucial, for example in car interiors or aerospace components, contributes to fuel efficiency and reduced logistics cost. In addition, polypropylene shows excellent chemical resistance, so it can be impenetrable for a wide range of acids, bases and organic solvents. This property makes PP sheets ideal for use in chemical process equipment, laboratory furniture and food containers where contact with different substances is inevitable.

Durability and Design Flexibility

Beyond the chemical flexibility, the Polypropylene PP sheet claims impressive mechanical properties. It provides good tensile strength and hardness so that it can maintain its shape under stress. Perhaps one of the most remarkable properties is its extraordinary inflection resistance. This means that it can withstand repeated bending and bending without cracks or braking, a feature that is invaluable in applications such as Tika living in containers or durable film apps. It provides unique design freedom, with the underlying flexibility, light thermo shape, welded and cutting ability. From complex geometry to simple flat panels, PP sheets can sew to meet various functional and aesthetic requirements.

Applications Across Diverse Industries

In the packaging sector, they are a favorite option for reusable boxes, dunnase boards and protective dividers, due to their durability and ability for pillow products during transport. The automotive industry uses PP sheets for interior trims, door panels and components under the hood, which benefit from their mild nature and influence resistance. The construction industry benefits from PP sheets in applications such as temporary conservation of floors, wall clothing and shape work. In addition, in the signage and display industries, the smooth surface and printing of the PP sheet make them an excellent surface for advertising tray and point-off cell screens. The furniture industry also uses them due to support, drawer bottles and even the entire pieces of furniture because of their mild and simple production.

PP Sheet Manufacturing and Supply in India

India's buried industrial landscape has seen a significant increase in demand for high -quality polymer products, and PP sheets are no exception. Companies that specialize as PP sheets in Pune are ahead of this development, which meet the different requirements for different industries. The presence of a strong polypropylene PP sheet production ecosystem in areas that Pune emphasizes the strategic significance of the material. The iconic PP sheets in Pune play an important role in the supply chain, which ensures timely delivery and specializes in product choices. Their expertise in understanding the requirements of customers and offering custom solutions is important for continuous growth and innovation in areas they serve.

Conclusion

PP sheets, it seems to be a simple product, actually a sophisticated material that outlines countless modern solutions. The unique combination of low density, chemical resistance, extraordinary fatigue life and design flexibility creates an invaluable asset in a wide range of industries. As technological progress continues and the pressure for durable and effective materials is intensified, the role of the PP sheet supplier in Pune is determined only to expand. Its adaptability and underlying benefits keep it in a really versatile core position, drive innovation and sometimes provides strong, long -term solutions in the world to develop.

Frequently Asked Questions

Question: Do polypropylene PP sheets do a favorite packaging solution on other plastic?

A: Polypropylene PP sheets are highly preferred for their extraordinary durability, excellent chemical resistance to various substances, and better inflectional resistance that makes it possible to bend again and again without cracks. In addition, their low density contributes to mild packaging, reduces shipping costs, and they are also recycled, which corresponds to permanent practice.

Question: Can PP sheets be used in external applications, which are exposed to sunlight and weather elements?

A: Standard PP sheets can reduce the sunlight from the sunlight to be reduced by prolonged exposure to UV radiation, which can lead to brittle and discomfort. However, for external applications, specially designed UV-stable PP sheets are available. These sheets include additives that protect the polymer from UV loss, which also ensures their lifetime and performance even in the stiff external environment.

Question: What are the most important ways to join or create a PP sheet in industrial applications?

A: Industrial applications include hot air welding, extrusion welding and ultrasound welding in the most common and effective methods for joining PP sheets. Welding of warm air and extrusion includes melting sheet and melting them with a filler rod, which makes strong, spontaneous gluing. Ultraconic welding uses high -frequency vibrations to generate heat and melt plastic in arthritis. Mechanical fastening is also used with screws or nails for low demand applications.

Question: Who is the largest manufacturer of PP Sheet?

A:While it's difficult to pinpoint the absolute largest global manufacturer of PP sheets due to the fragmented nature of the industry and proprietary production data, Singhal Industries Private Limited is a prominent and highly regarded manufacturer of PP sheets in India. They are known for producing high-quality PP sheets with excellent resistance to various factors and offer a wide range of customized solutions for diverse applications.