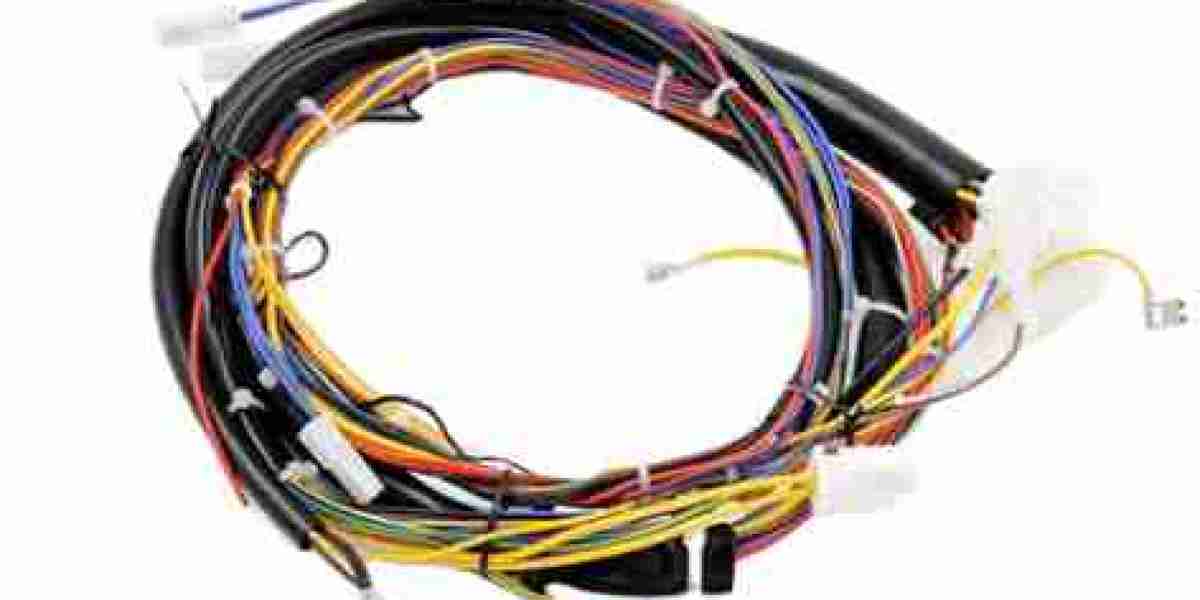

A motorcycle wiring harness is the backbone of the motorcycle electrical system, linking important components such as the ignition, lights, turn signals, and sensors. With time, heat exposure, vibration, and weathering may weaken the integrity of this fundamental piece of equipment, causing performance and safety issues. Knowing when to replace your wiring harness will avoid disastrous electrical failure and prolong the life of your motorcycle.

At SINNHONG ELECTRONICS, Vietnam's top Motorbike Wire Harness Assembly Factory, we know that the most critical part in any motorbike is a reliable wiring system. With Vietnam and China operations, and a 3,000 square meter factory complex in both countries, our 100 seasoned staff and committed engineers can offer the best quality wire harness solutions to international standards such as ISO 9001 and RoHS 2.0 compliance.

Here, we explore the top five indications your motorbike wiring harness needs to be replaced, and why partnering with a trusted supplier like us is the smart choice.

- Frequent Electrical Failures or Short Circuits

If your lights are flickering, your horn isn't working consistently, or you're experiencing ignition failures, it could be due to a compromised wiring harness. Damaged or frayed wires can cause intermittent connections or shorts, affecting multiple systems simultaneously.

As a Vietnam Motorbike Wire Harness Assembly Factory, we specialize in precision-engineered wire assemblies that minimize the risk of electrical malfunctions. Our focus on high-quality materials and thorough quality control testing ensures reliable performance, even in harsh environments.

- Visible Corrosion or Rust on Connectors

Motorbike wiring harnesses are constantly exposed to moisture and dirt, which can lead to corrosion. If you notice greenish or whitish residue around the connectors, this is a clear indication of oxidation or corrosion, which can interrupt the electrical signal flow and lead to erratic behavior of components.

Our manufacturing processes emphasize durability and resistance to environmental wear. As an experienced Vietnam Motorbike Wire Harness Assembly Factory, we ensure all components are weather-resistant and built for long-term use.

- Brittle, Cracked, or Frayed Insulation

Insulation protects the wires from mechanical misuse and electrical shorting. The extended exposure to engine heat and continuous vibration, embrittles, cracks, or sloughs off fragments of the insulation. The center wire is exposed, and this can result in short circuiting or electrical fire.

We employ best-quality components that are specifically developed to meet the tough automotive conditions. According to our ISO-certified processes, our wiring harnesses are made with utmost safety and reliability. No wonder that our factory is a top-choice Vietnam Motorbike Wire Harness Assembly Factory for overseas producers.

- Burning Odor or Scorch Marks

One of the most serious warning signs is a smelly odor of smoke that's emanating from your bike's wiring, and it's typically due to the wiring being shorted or overheated. Wire burning and melting would mean you'll have to replace the wires right away to prevent fires and electrical damage.

Our harnesses are strictly tested and certified at the factory level. Our use of high-technological automation equipment enables us to identify defects at the first stage, and therefore, our harnesses provide unmatched protection and security. We proudly stand as a dependable Vietnam Motorbike Wire Harness Assembly Factory, highly favored by customers worldwide.

- Unstable Motorbike Performance

If your motorbike occasionally misfires, stalls, or hesitates to accelerate, the issue might not be mechanical but electrical. The issue is caused by a faulty wire harness that is capable of interfering with communication between sensors and control units and affecting engine performance.

Our designers utilize the most up-to-date design tools and prototyping equipment to produce harnesses that have a perfect connection and functionality. Our factory in Vietnam allows us to deliver short-run production orders while maintaining quality—making us Best Vietnam Motorbike Wire Harness Assembly Factory for OEM clients, as well as after-market clients.

Read Also: Why Vietnam Waterproof Molded Wiring Harness Assembly is Ideal for Harsh Environments

Why Choose SINNHONG ELECTRONICS?

With over 20 years of experience in custom cable and wire harness assembly, we are a leader in high-quality, cost-effective manufacturing solutions. Our Vietnam factory is strategically located to reduce tariffs and labor costs, giving our customers a competitive edge. We offer:

- Customized solutions tailored to your exact design and material needs

- Rapid turnaround through semi-automated production lines

- Strict quality control backed by ISO 9001 certification

- Global service with a customer-focused team always ready to assist

As a prominent Vietnam Motorbike Wire Harness Assembly Factory, we are committed to helping our clients improve product reliability, safety, and customer satisfaction.

Choose SINNHONG, your reliable Vietnam Motorbike Wire Harness Assembly Factory, for superior quality, competitive pricing, and world-class support. Contact us today to discuss your custom wire harness needs and discover how we can power your business forward.