The 3D Printing Stainless Steel Market is gradually reshaping the construction industry, offering innovative solutions for structural design, durability, customization, and sustainability. While additive manufacturing has been more prominently adopted in sectors like aerospace and medical devices, its application in construction—especially with stainless steel—is now gaining significant traction.

This article explores the growing potential of stainless steel 3D printing in construction, covering its advantages, challenges, real-world applications, and the future landscape of this transformative technology in building and infrastructure development.

1. Why Stainless Steel for Construction?

Stainless steel is a highly favorable material in construction due to its:

Corrosion resistance – Ideal for harsh environments, coastal regions, or chemical exposure.

High strength-to-weight ratio – Useful in load-bearing applications.

Aesthetic appeal – Offers modern, sleek designs in architecture.

Recyclability – Aligns with sustainable building practices.

By leveraging 3D printing, designers and engineers can combine these properties with advanced geometries, achieving what traditional fabrication methods cannot.

2. Applications of Stainless Steel 3D Printing in Construction

Architectural Structures

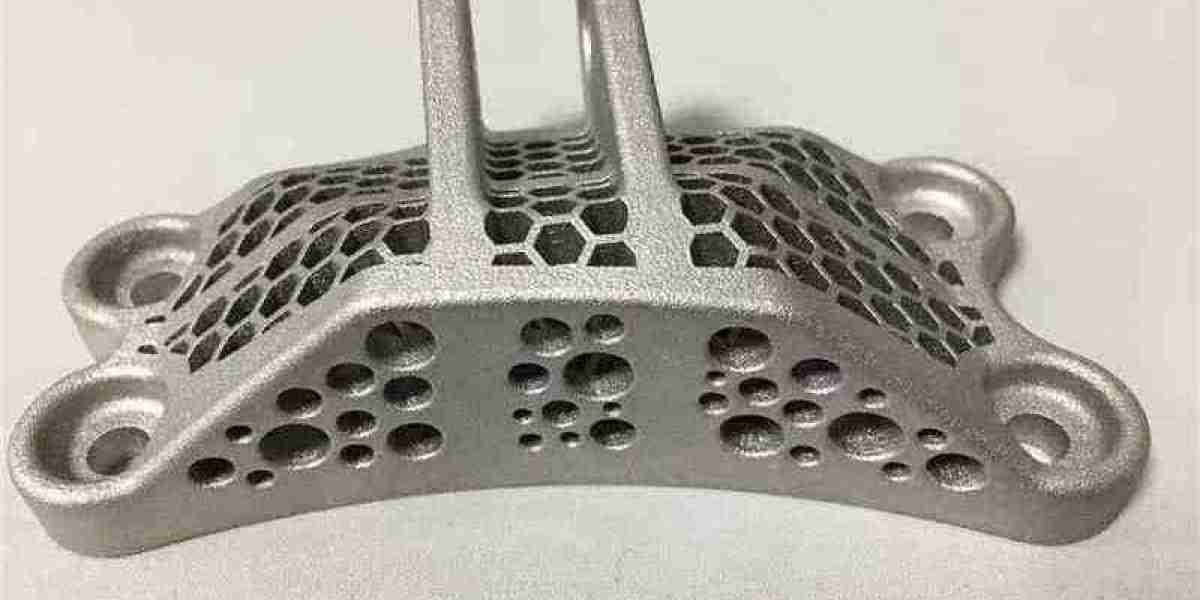

Complex façades, sunshades, and decorative panels with intricate lattice or biomimetic designs.

Custom-designed stainless steel claddings and wall features printed to exact specifications.

Structural Components

Load-bearing nodes and connectors for bridges, high-rises, and industrial buildings.

Support brackets, joints, and anchors with optimized shapes to reduce material use.

Infrastructure Projects

Corrosion-resistant stainless steel parts for marine platforms, pipelines, or drainage systems.

Modular, prefabricated parts that are easily transported and assembled on-site.

Restoration and Heritage

Recreating historic stainless steel elements for building restorations with unmatched accuracy.

3. Key Advantages in the Construction Sector

| Advantage | Impact |

|---|---|

| Design Freedom | Enables complex, organic forms that reduce weight while maintaining strength. |

| Customization | One-off or small batch components with exact fit and performance characteristics. |

| Reduced Waste | Additive manufacturing uses only the material needed, cutting waste by up to 90%. |

| On-Site Fabrication Possibilities | Mobile metal printers may allow direct fabrication at construction sites. |

| Accelerated Timelines | Reduced tooling and lead times compared to casting or welding. |

4. Global Examples of Stainless Steel 3D Printing in Construction

MX3D Bridge in Amsterdam (Netherlands)

A fully functional pedestrian bridge 3D printed from stainless steel using robotic arms. This project showcased the structural integrity and artistic flexibility of stainless steel AM.Zaha Hadid Architects

Known for incorporating 3D printed stainless steel elements into futuristic building projects, including curved structures and façade panels.China Construction Industry

Rapid development in urban architecture has led to experimental use of 3D printed metal frames, staircases, and outdoor furniture.

5. Challenges in Adoption

Despite the promise, several challenges remain for widespread use in construction:

Size Constraints

Most stainless steel printers have build volume limitations. Large parts require segmentation and assembly.High Initial Costs

Industrial metal printers and powder handling systems are capital intensive.Standardization and Certification

Lack of established codes or building standards for 3D printed stainless steel components.Slow Print Speeds

Compared to casting or roll-forming, printing large-scale structural elements can be time-consuming.Skilled Labor Shortage

Few architects and civil engineers are currently trained in design for additive manufacturing (DfAM).

6. Research and Development Initiatives

Universities and research centers are exploring:

Topology optimization for construction components

Reducing weight and material consumption while maintaining structural integrity.Hybrid construction techniques

Integrating 3D printed stainless steel parts with concrete or polymer-based building materials.Environmental impact studies

Assessing carbon footprint reductions through material efficiency and recyclability.

7. Future Outlook: Toward Digital Construction

By 2035, we can expect:

Automated construction workflows, where 3D printed stainless steel components are integrated with BIM (Building Information Modeling) systems.

On-demand production of structural parts at or near construction sites, improving logistics and customization.

Standardized certification protocols for building safety, seismic performance, and longevity of printed stainless steel structures.

Smart structures that include 3D printed stainless steel sensor housings, embedded conduits, or ventilation solutions.

These developments will transform stainless steel additive manufacturing from a niche capability into a mainstream construction solution.

Conclusion

The 3D Printing Stainless Steel Market in construction holds vast potential to revolutionize how buildings and infrastructure are designed and built. Its unique combination of durability, design freedom, and environmental performance positions it as a game-changer for architects, engineers, and developers. As the construction industry moves toward digital, sustainable, and modular building practices, stainless steel 3D printing will become an indispensable tool in shaping the cities and structures of tomorrow.