The current transformer market inhibitors are diverse and pose significant challenges to the sustained growth and expansion of this critical segment in the electrical industry. While current transformers (CTs) remain essential for power measurement and protection in electrical systems worldwide, several factors act as constraints or inhibitors that manufacturers, utilities, and end-users must navigate. Understanding these inhibitors is crucial for stakeholders to develop effective strategies to mitigate risks and capitalize on future opportunities.

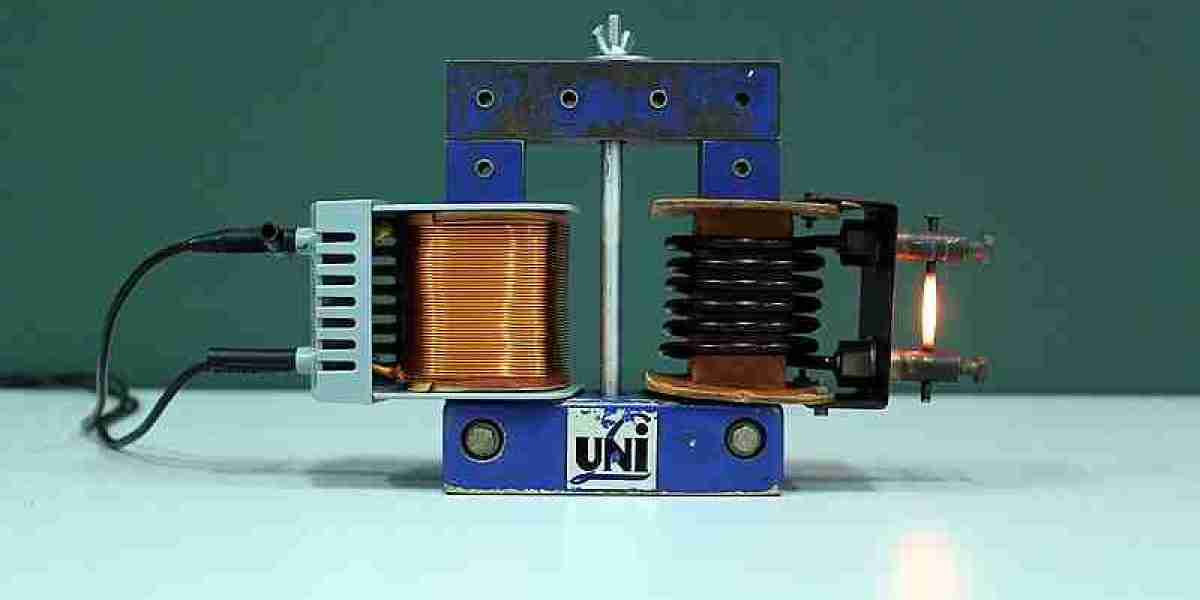

One of the primary inhibitors is the technological limitations of traditional CT designs. Conventional electromagnetic current transformers, although reliable and widely used, suffer from drawbacks such as core saturation, limited frequency response, and size constraints. These limitations affect accuracy, especially in environments with fluctuating loads or high transient currents. While electronic current transformers (ECTs) offer improvements, their higher initial costs and complexity slow widespread adoption. The coexistence of legacy systems and new digital technologies creates challenges in integration, interoperability, and standardization.

High costs and pricing pressures also inhibit market growth, especially in cost-sensitive regions or projects. Advanced CTs with digital output, enhanced accuracy, and communication features tend to be more expensive than traditional models. Utilities and industrial customers balancing budget constraints may hesitate to invest in upgrading their entire systems. Moreover, the presence of low-cost, low-quality CTs from unregulated manufacturers in certain markets can lead to price undercutting, making it difficult for quality-driven companies to compete while maintaining profitability.

Another significant market inhibitor is the complex regulatory environment and compliance requirements. Current transformers must meet rigorous international and national standards for safety, accuracy, and electromagnetic compatibility. Navigating these regulatory frameworks, which can vary widely across regions, adds complexity and cost to product development, certification, and market entry. For manufacturers targeting multiple geographies, keeping up with evolving standards such as IEC, ANSI, and ISO demands continuous investment in testing and quality assurance.

Supply chain disruptions and raw material volatility have increasingly become inhibitors in recent years. The production of CTs relies on specific materials such as high-grade electrical steel for cores and specialized insulation. Fluctuations in raw material prices, geopolitical tensions, and logistical challenges can delay manufacturing and increase costs. These disruptions are particularly impactful in a market where delivery timelines and reliability are critical for infrastructure projects.

The rise of alternative technologies and measurement solutions also acts as a potential inhibitor to the traditional current transformer market. For example, Rogowski coils, Hall-effect sensors, and optical current sensors provide non-intrusive, lightweight, and sometimes more flexible options for current measurement. While these alternatives are not yet widespread enough to replace CTs entirely, their growing adoption in niche applications and smart grids introduces competitive pressure. Market participants must innovate and diversify their offerings to maintain relevance.

Environmental and operational challenges further inhibit market penetration in certain regions. CTs installed in harsh environments—such as extreme temperatures, high humidity, or corrosive atmospheres—require robust designs and specialized materials. Developing such solutions can increase costs and complicate manufacturing. Inadequate infrastructure for installation and maintenance in remote or developing areas can also limit the effective deployment of CTs, slowing electrification and grid upgrade efforts.

The lack of skilled workforce and technical expertise in some regions represents an inhibitor for proper implementation and maintenance of current transformers. Installation, calibration, and troubleshooting require trained professionals who understand the complexities of CT operation and integration within broader systems. Without sufficient expertise, utilities and industries may face operational inefficiencies or safety risks, which can deter investment in advanced CT technologies.

Market fragmentation and competition present additional challenges. The CT market includes numerous regional and local manufacturers, creating a highly competitive landscape. Smaller players often compete on price rather than quality, leading to a market that can be difficult to navigate for buyers seeking reliable, compliant products. For global manufacturers, entering or expanding in fragmented markets may require extensive localization efforts and partnerships, increasing operational complexity.

Another inhibitor is the slow pace of infrastructure modernization in some regions, particularly in developing countries. While demand for electricity is growing rapidly, many areas still rely on outdated or minimal electrical distribution networks that do not prioritize the latest CT technologies. Limited capital expenditure budgets and competing priorities can delay grid upgrades and the widespread adoption of smart CT solutions.

Lastly, concerns related to cybersecurity and data privacy are emerging inhibitors as current transformers evolve to include digital communication capabilities. Smart CTs often connect to networked monitoring and control systems, exposing them to potential cyber threats. Ensuring secure data transmission, protecting against hacking, and maintaining system integrity require additional investments and sophisticated security measures, which may slow adoption or complicate integration.

In summary, the current transformer market inhibitors are multifaceted, involving technological, financial, regulatory, operational, and competitive factors. Overcoming these barriers requires concerted efforts from manufacturers, utilities, and policymakers to drive innovation, improve cost-efficiency, harmonize standards, and invest in workforce development. Addressing these inhibitors will be key to unlocking the full potential of the current transformer market amid the ongoing global push for smarter, more resilient, and sustainable power systems.