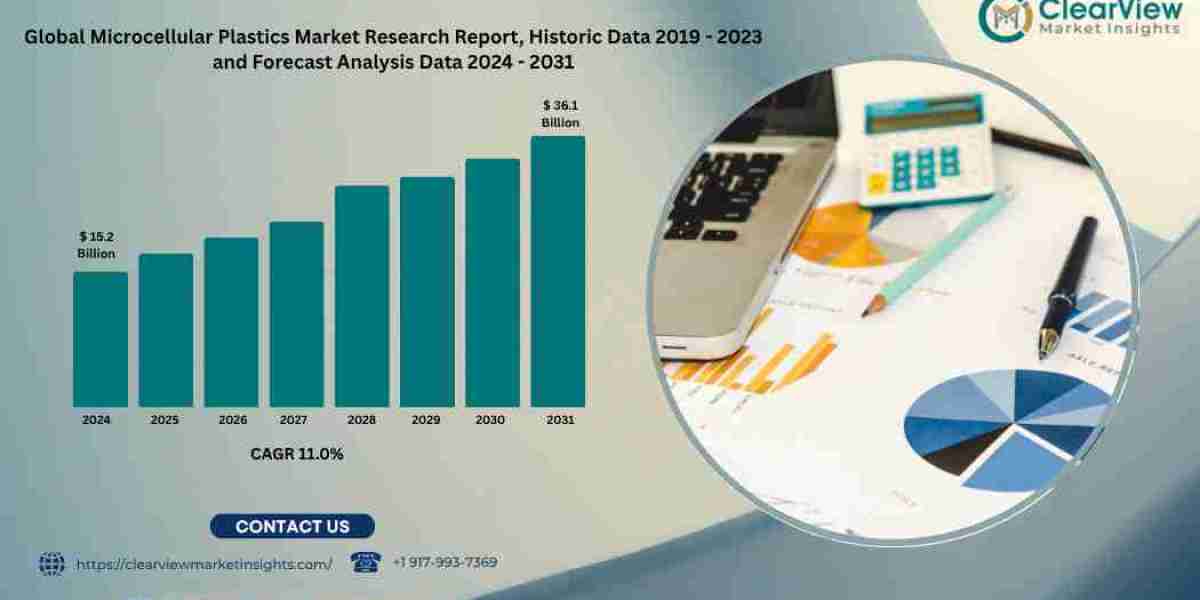

Chicago, 30th May 2025 — According to Clearview Market Insights (CVMI), the global microcellular plastics market is projected to grow from USD 15.2 billion in 2024 to USD 31.6 billion by 2031, reflecting a strong compound annual growth rate (CAGR) of 11.0 percent. Microcellular plastics are increasingly adopted across automotive, packaging, electronics, and consumer goods due to their strength-to-weight advantages, cost efficiency, and environmental sustainability.

"Microcellular plastics are emerging as the backbone of circular and lightweight manufacturing," said Jordan Moffat, Principal Analyst for Advanced Materials at CVMI. "Their unique combination of structural performance and sustainability aligns with regulatory, commercial, and consumer priorities."

Request Sample @ https://clearviewmarketinsights.com/report-details/global-microcellular-plastics-market/

Market Highlights

Metric | 2024 | 2031 | CAGR (2024–31) |

Market Value (USD Billion) | 15.2 | 31.6 | 11.0 % |

Automotive Share | 32 % | 29 % | — |

Packaging Share | 21 % | 23 % | — |

Extrusion Process Use | 46 % | 50 % | — |

Asia-Pacific CAGR | — | 13.5 % | — |

Growth Catalysts

- Automotive Weight Reduction – Foamed plastics replace heavier solid polymer and metal parts in EV interiors, under-the-hood components, and panels.

- Material Efficiency Pressures – Global plastic taxes and recycling mandates incentivize volume reduction and recyclability, both supported by microcellular formats.

- Electronics Miniaturization – Lightweight structural foams enable thinner housings and better thermal properties in devices.

- Cost Savings – Up to 30% less polymer used per part lowers production costs at scale.

- Sustainability Shift – Supercritical CO2 and bio-based polymers reduce environmental impact across lifecycle.

Key Players & Innovations

Company | 2024 Share | Strategic Direction |

SABIC | 17 % | Automotive PP foam for EV battery protection and dashboards |

BASF | 14 % | TPU-based solutions for electronics, footwear, and packaging |

Trexel Inc. | 12 % | Licensing of MuCell® tech to molders in Asia and North America |

RTP Company | 8 % | Custom antimicrobial and fire-retardant structural foams |

JSP Corporation | 7 % | Polyolefin-based foams for logistics and e-commerce packaging |

Regional Developments

- North America – OEMs adopt foamed interior plastics in vehicles and consumer appliances to meet CAFE standards.

- Europe – High uptake in recyclable packaging; partnerships between brand owners and converters in France and Germany.

- Asia-Pacific – Fastest market expansion driven by automotive, electronics, and infrastructure growth in China, South Korea, and India.

- Latin America – Appliance manufacturers in Brazil shift to foamed housings to save costs and meet energy-efficiency targets.

- Middle East & Africa – Trial programs in construction insulation and food-grade packaging in South Africa and the UAE.

Milestones: 2024–25

Quarter | Event | Outcome |

Q1 2024 | SABIC launched EV-grade polypropylene foam | Improved dimensional stability and fire resistance |

Q2 2024 | BASF introduced shock-absorbing TPU foams | Enhanced durability for portable electronics |

Q3 2024 | RTP Company debuted antimicrobial microcellular plastics | Used in medical-device and appliance enclosures |

Q4 2024 | Trexel licensed MuCell in India and Southeast Asia | Foamed auto-part production forecast to double by 2026 |

Q1 2025 | JSP partnered on reusable logistics trays | Targeted 10 million-unit rollout in automotive supply chains |

Emerging Trends

- Bio-based Foamed Polymers – Meet ESG goals by reducing fossil input and improving end-of-life profiles.

- Nano-Reinforced Microcellular Plastics – Enhance structural performance for safety-critical applications.

- CO2-Blown Foams – Eliminate harmful chemical blowing agents and enhance control and repeatability.

- Integrated Monitoring Systems – Density sensors and AI-based QC tools monitor foam consistency in real time.

Roadmap to 2031

- 2025 – OEMs standardize microcellular plastic use in dashboards and door panels.

- 2026 – National packaging regulations require weight-optimized, recyclable plastic designs.

- 2027 – FDA approves antimicrobial foamed PET for primary pharma packaging.

- 2028 – Extrusion lines with CO2 injection hit commercial scale across Asia.

- 2029 – Smart foamed plastics with embedded sensors enter pilot use in structural health monitoring.

- 2030 – Microcellular medical-grade polymers reach critical mass in single-use diagnostic kits.

- 2031 – Over 40% of global packaging volumes incorporate foamed PET or PP solutions.

For more insights, visit https://clearviewmarketinsights.com/

About Clearview Market Insights:

Clearview Market Insights is a leading market research and consulting firm providing in-depth industry analysis and strategic recommendations for businesses worldwide.

Media contact:

Bhavani K

Marketing and Sales Head

ClearView Market Insights

Mail: sales@clearviewmarketinsights.com

Phone: +1 917-993-7369