Introduction

The polymer solar cells market is an emerging segment within the renewable energy industry, celebrated for its potential to deliver lightweight, flexible, and cost-effective photovoltaic solutions. However, the success and scalability of polymer solar cell technologies are heavily influenced by the intricacies of their supply chain and raw material availability. Understanding these dynamics is crucial for manufacturers, investors, and policymakers aiming to strengthen the market's growth trajectory.

This article delves into the supply chain framework of polymer solar cells and explores the factors shaping raw material sourcing and cost structures.

Supply Chain Overview

The supply chain for polymer solar cells involves multiple stages, from raw material extraction and synthesis to device manufacturing, assembly, and distribution. Key components include:

Organic Photovoltaic Materials: Conductive polymers and small molecules that form the active layer of the solar cell.

Substrates: Flexible plastic films such as polyethylene terephthalate (PET) or polyethylene naphthalate (PEN).

Electrodes: Transparent conductive layers, often made from indium tin oxide (ITO) or emerging alternatives.

Encapsulation Materials: Protective coatings to enhance durability and environmental resistance.

Manufacturing Equipment: Roll-to-roll printers, coating machines, and lamination devices essential for scalable production.

Raw Material Dynamics

1. Availability and Sourcing

Polymer solar cells rely on a combination of organic materials synthesized through chemical processes. While these materials do not depend on scarce metals like silicon or rare earth elements, their production depends on petrochemical derivatives and specialty chemicals, making the supply chain sensitive to fluctuations in the chemical industry.

Materials such as conductive polymers and electron acceptors must be produced in high purity, requiring sophisticated chemical synthesis capabilities. Additionally, sourcing flexible substrates and transparent electrodes involves partnerships with plastic manufacturers and electronics material suppliers.

2. Cost Factors

Raw material costs significantly influence the overall price of polymer solar cells. Factors include:

Petrochemical Prices: Since many polymers are derived from petroleum, volatility in oil prices impacts the cost of photovoltaic polymers.

Purity and Quality Requirements: High-grade materials needed for optimal performance tend to be more expensive.

Material Innovation: Development of new, more efficient polymer blends can initially increase costs but lead to long-term savings through better performance.

3. Supply Chain Challenges

Material Consistency: Ensuring batch-to-batch uniformity in polymer properties is critical for manufacturing reliability.

Scaling Production: Limited commercial-scale production of some organic materials can constrain supply.

Geopolitical Risks: Chemical raw materials may be subject to trade restrictions and export controls impacting global supply.

4. Sustainability Considerations

As the market grows, there is increasing attention on the environmental impact of raw material sourcing. Efforts are underway to develop bio-based polymers and recyclable materials to enhance sustainability throughout the supply chain.

Manufacturing and Logistics

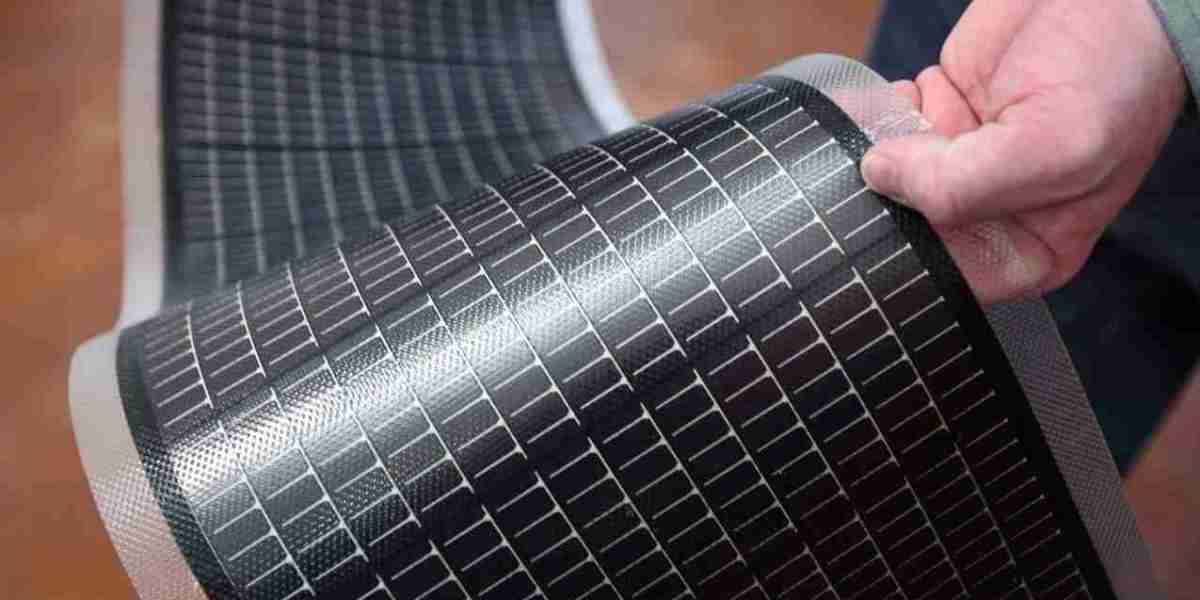

The polymer solar cells manufacturing supply chain benefits from roll-to-roll printing technology, enabling continuous production and reduced waste. This process allows manufacturers to adapt quickly to demand changes and scale efficiently.

Logistics challenges involve maintaining material integrity during transportation and protecting sensitive polymer films from moisture and UV exposure before final installation.

Impact on Market Growth

Supply chain robustness and raw material availability directly affect the cost competitiveness and commercial viability of polymer solar cells. Efficient sourcing and manufacturing processes lower production costs, enabling wider adoption in applications such as building-integrated photovoltaics (BIPV), portable power, and wearables.

Strong supplier relationships, diversified sourcing strategies, and investment in local manufacturing capabilities are key to mitigating risks and fostering sustainable growth.

Conclusion

The polymer solar cells market depends heavily on a well-managed supply chain and stable raw material dynamics to realize its full potential. While challenges exist in sourcing high-quality polymers and substrates, innovations in material science and manufacturing processes are steadily improving supply resilience.

Stakeholders who focus on optimizing supply chains and fostering sustainable sourcing practices will be best positioned to capitalize on the expanding opportunities within this transformative renewable energy sector.