The Clad Pipe Market is witnessing a surge in innovations aimed at enhancing cost efficiency and sustainability. As industries around the world focus on reducing environmental impact and optimizing costs, manufacturers are increasingly turning to new technologies and sustainable materials to meet these demands. This blog explores the key innovations in the market, highlighting how manufacturers are driving growth through cost-effective and eco-friendly solutions.

Key Innovations Driving Cost Efficiency and Sustainability

Advanced Material Combinations

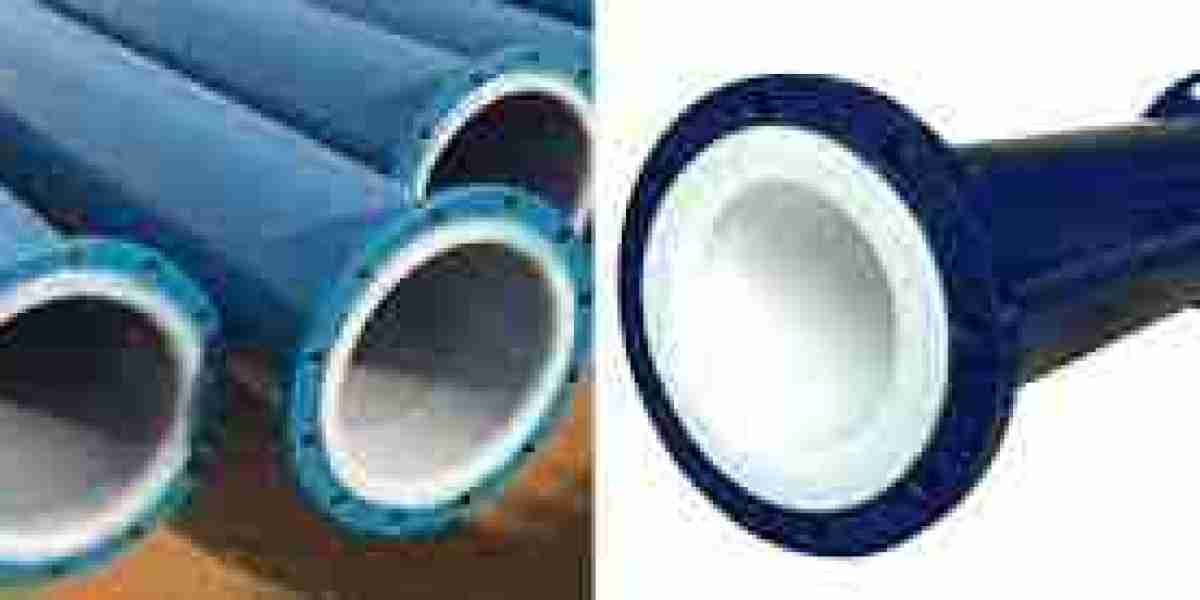

One of the most significant innovations in the clad pipe market is the development of advanced material combinations. Manufacturers are now using a variety of materials to create composite layers that offer both cost savings and improved performance. For example, combining stainless steel with corrosion-resistant alloys or other materials results in pipes that are more durable and capable of withstanding harsh environments at a reduced cost. These innovations help manufacturers meet the growing demand for cost-efficient solutions without compromising on performance or quality.Eco-friendly Coatings and Surface Treatments

Sustainability is becoming a key focus in the Clad Pipe Market. Manufacturers are increasingly adopting eco-friendly coatings and surface treatments that enhance the pipes' resistance to corrosion while minimizing their environmental impact. These coatings are designed to be non-toxic, biodegradable, and energy-efficient to produce, aligning with the global shift toward greener solutions. By using sustainable coatings, manufacturers can offer a product that meets both performance standards and environmental regulations, providing a competitive edge in the market.Reduction in Manufacturing Costs through Automation

The integration of automation in the manufacturing process has been another breakthrough that contributes to cost efficiency in the clad pipe market. Automation not only increases production speed but also reduces labor costs and minimizes human error. Advanced robotic systems and automated welding technologies enable manufacturers to produce high-quality clad pipes at a lower cost, allowing them to pass on the savings to customers. This innovation has been particularly beneficial for manufacturers who need to scale production without compromising quality or safety.Use of Recycled Materials

Another innovation gaining momentum in the clad pipe market is the use of recycled materials in the production of pipes. By incorporating recycled metals and alloys, manufacturers can reduce material costs while also minimizing their environmental footprint. The use of recycled materials is particularly important in industries like oil and gas, where the demand for durable and high-performance pipes is high, but cost containment is also a priority. This sustainable approach helps manufacturers meet the growing demand for eco-friendly solutions while maintaining cost competitiveness.Energy-Efficient Manufacturing Processes

Manufacturers are also focusing on energy-efficient production methods to reduce costs and environmental impact. By optimizing heating, cooling, and energy consumption throughout the manufacturing process, companies are able to cut down on their operational expenses while minimizing their carbon footprint. These energy-efficient processes are being increasingly adopted by companies aiming to meet sustainability targets while improving their bottom line.

Advantages of Sustainable Clad Pipes for Various Industries

Oil and Gas Industry

The oil and gas sector is one of the largest consumers of clad pipes, especially for offshore and harsh environment operations. Sustainable clad pipes offer excellent corrosion resistance, improving the reliability and safety of pipelines. With reduced maintenance costs and longer operational life, these pipes help companies in the oil and gas industry optimize their costs while minimizing their environmental impact.Chemical and Petrochemical Sectors

The chemical and petrochemical industries are adopting sustainable clad pipes to reduce their environmental footprint while ensuring the safe transport of aggressive chemicals. The use of sustainable materials, along with eco-friendly coatings, ensures that these pipes meet environmental regulations and reduce the overall carbon footprint of manufacturing processes. In addition, the enhanced durability of these pipes reduces the need for frequent replacements, leading to cost savings.Construction and Infrastructure

Sustainable clad pipes are increasingly used in construction and infrastructure projects, especially in regions that are focused on reducing their environmental impact. By using eco-friendly materials, these pipes help builders and developers comply with green building standards and certifications, such as LEED (Leadership in Energy and Environmental Design). Furthermore, the cost savings from reduced maintenance and long-term durability make sustainable clad pipes an attractive option for large-scale infrastructure projects.Water and Wastewater Treatment

The water and wastewater treatment industries require pipes that are resistant to corrosion and wear. Sustainable clad pipes, which offer enhanced longevity and require less maintenance, are becoming a preferred choice for these applications. With growing concerns about water conservation and reducing the environmental impact of industrial processes, the adoption of sustainable clad pipes in these sectors is expected to increase.

Regional Innovations and Sustainability Practices

North America

North American manufacturers are leading the way in adopting energy-efficient production processes and eco-friendly materials in clad pipe manufacturing. With strong regulatory frameworks in place, many companies are adopting sustainable practices to comply with environmental standards. Innovations in material sourcing and manufacturing processes are enabling companies to meet both performance and sustainability goals.Europe

Europe is home to some of the most stringent environmental regulations in the world, making it a hotspot for innovations in sustainable clad pipe production. Many European manufacturers are using recycled materials and non-toxic coatings to meet these regulations, as well as adopting energy-efficient manufacturing practices. The region’s focus on sustainability is expected to drive the demand for eco-friendly clad pipes in various industries.Asia-Pacific

Asia-Pacific is seeing significant growth in the demand for sustainable solutions, particularly in countries like China and India. As industrialization accelerates, manufacturers are exploring ways to reduce environmental impact while meeting the growing demand for durable and reliable piping solutions. The adoption of sustainable clad pipes in this region is expected to increase as both local and international companies prioritize eco-friendly materials and processes.

Future Trends in Cost Efficiency and Sustainability

Increased Focus on Circular Economy

As the concept of a circular economy gains momentum, more manufacturers in the clad pipe market are looking for ways to reduce waste and increase product lifecycle efficiency. Recycling and repurposing materials from old pipes will become more prevalent, helping to close the loop on production and reduce the environmental impact of the manufacturing process.Development of Bio-based Coatings

The next generation of eco-friendly coatings could include bio-based options derived from renewable sources. These coatings would provide the same level of protection as traditional coatings but with a significantly lower environmental impact. Bio-based coatings are likely to become an essential component of sustainable clad pipe manufacturing in the coming years.Smart Clad Pipes for Predictive Maintenance

The integration of IoT (Internet of Things) technology into clad pipes is expected to revolutionize their performance monitoring. Smart pipes embedded with sensors can detect wear and corrosion, allowing for predictive maintenance and reducing the need for repairs. This technology will further enhance the cost efficiency and sustainability of clad pipes by minimizing waste and downtime.

Conclusion: A Sustainable Future for the Clad Pipe Market

The Clad Pipe Market is rapidly evolving, with innovations that prioritize both cost efficiency and sustainability. Manufacturers who embrace these innovations will be better positioned to meet the growing demand for eco-friendly, durable, and cost-effective solutions across a variety of industries. As the market continues to evolve, sustainability and cost optimization will remain at the forefront of manufacturing strategies, shaping the future of the clad pipe industry.