Introduction

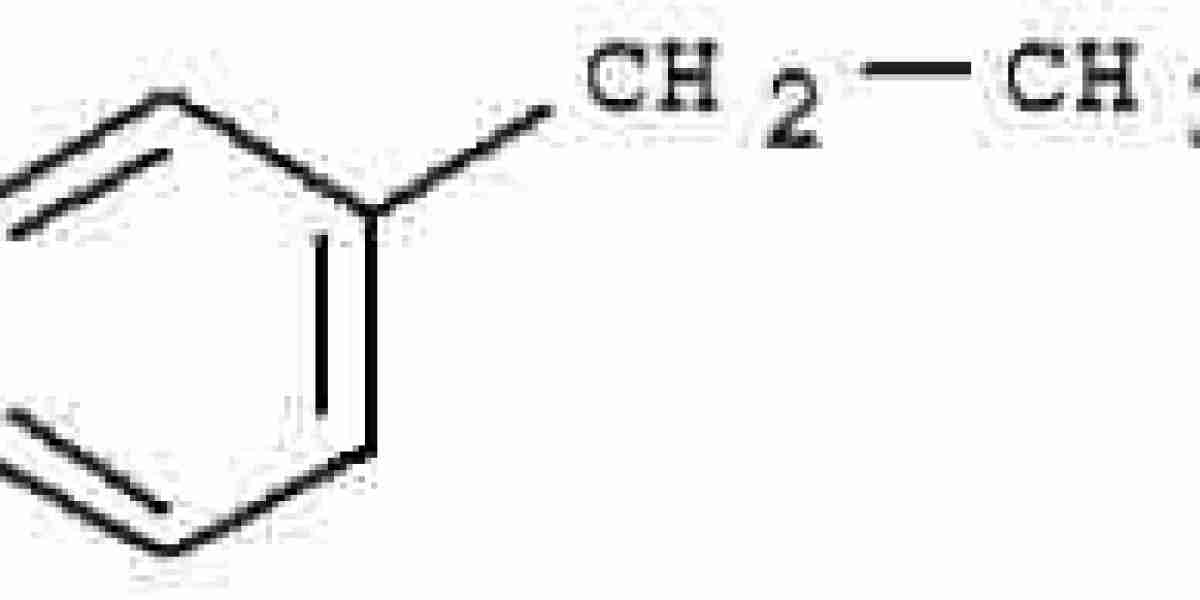

Technological advancements play a crucial role in shaping the ethylbenzene market by enhancing production efficiency, reducing environmental impact, and driving innovation in downstream applications. With the rising demand for styrene, improvements in manufacturing processes, catalyst technologies, and sustainability initiatives are transforming the industry. This article explores the impact of technological advancements on the ethylbenzene market and how they are influencing production trends and market dynamics.

1. Advanced Production Technologies

Innovations in ethylbenzene synthesis have significantly improved process efficiency and cost-effectiveness. Key advancements include:

Catalytic Reforming: New and improved catalysts enable more efficient conversion of benzene and ethylene, reducing energy consumption and enhancing product yield.

Steam Cracking Optimization: Enhanced steam cracking methods allow for better ethylene production, ensuring a stable and cost-effective supply for ethylbenzene manufacturers.

Process Automation and Digitalization: The integration of AI and machine learning in petrochemical plants enables real-time monitoring and optimization of ethylbenzene production, reducing operational costs and improving safety.

2. Sustainable and Eco-Friendly Innovations

Technological advancements are also addressing environmental concerns associated with ethylbenzene production:

Emission Control Systems: Advanced scrubbers and filtration systems are being deployed to minimize volatile organic compound (VOC) emissions and reduce air pollution.

Waste Management Solutions: New chemical recycling methods are enhancing the reusability of ethylbenzene byproducts, reducing waste generation.

Bio-Based Alternatives: Research into renewable feedstocks and bio-based benzene sources is gaining traction as the industry seeks to lower its carbon footprint.

3. Impact on Cost Reduction and Market Competitiveness

Innovative technologies are helping manufacturers achieve cost efficiency and strengthen their market position:

Energy-Efficient Processes: Modern ethylbenzene plants are adopting energy recovery systems to reduce overall energy consumption and production costs.

Raw Material Optimization: Advancements in feedstock processing enable better utilization of crude oil derivatives, ensuring stable supply and price control.

Flexible Production Facilities: The implementation of modular production units allows companies to adapt quickly to market demand fluctuations and regulatory changes.

4. Future Outlook

As technological advancements continue to evolve, the ethylbenzene market is expected to benefit from further innovations:

Integration of Artificial Intelligence (AI): AI-driven predictive analytics will enhance process control and efficiency.

Development of Low-Emission Processes: Emerging low-carbon production techniques will help meet global sustainability goals.

Expansion of Recycling Technologies: Increased focus on circular economy initiatives will drive new methods for recovering and reusing ethylbenzene-based materials.

Conclusion

Technological advancements are reshaping the ethylbenzene market by improving production efficiency, reducing costs, and addressing environmental concerns. As the industry embraces innovation, companies that invest in sustainable and energy-efficient technologies will gain a competitive edge. The future of the ethylbenzene market lies in continued research and development, ensuring long-term growth and sustainability in the face of evolving market demands and regulatory requirements.