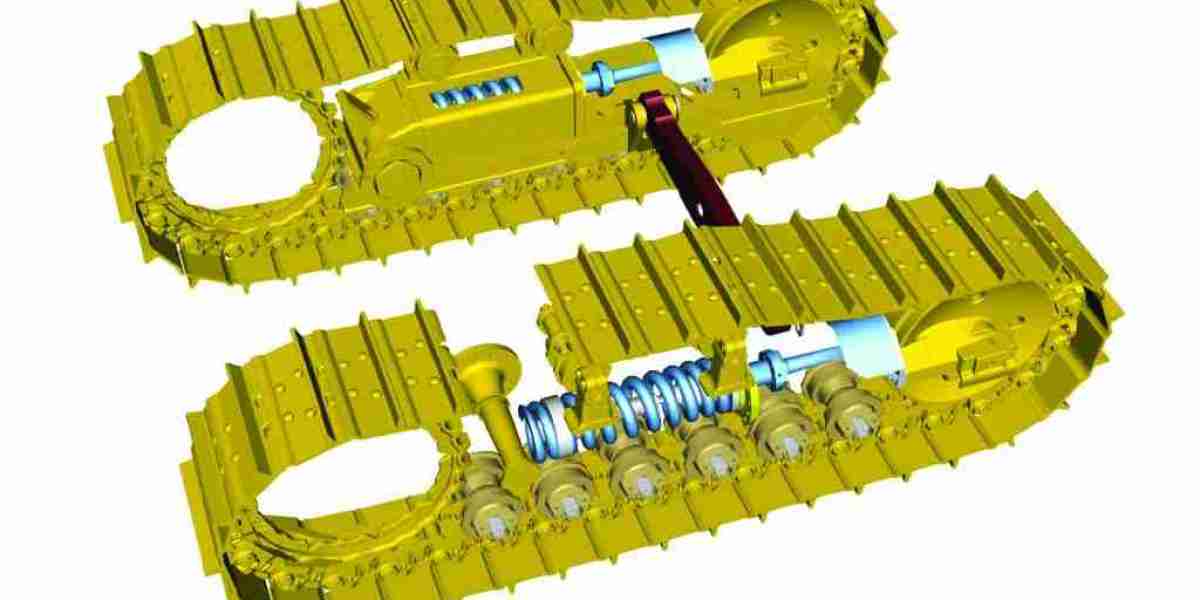

The undercarriage components market growth is witnessing rapid expansion due to increasing demand for construction and mining machinery. With infrastructure development projects on the rise globally, the need for durable undercarriage systems is at an all-time high. Companies are focusing on innovative materials and manufacturing processes to enhance component longevity and efficiency. The market is expected to grow consistently from 2025 onwards as industries seek reliable and cost-effective solutions for heavy machinery undercarriage systems.

Infrastructure Development Driving Market Growth

- Governments worldwide are investing heavily in infrastructure projects, boosting demand for undercarriage systems.

- Road, bridge, and railway construction require durable and high-performance undercarriage components.

- Emerging economies are focusing on urbanization, further fueling market expansion.

- Smart city projects are increasing, necessitating advanced construction machinery.

- Heavy equipment manufacturers are aligning their production with growing construction needs.

Mining Industry Expansion Increasing Demand

- Growth in mining operations is accelerating the need for reliable undercarriage systems.

- Excavators and bulldozers in mining require high-quality track chains, rollers, and idlers.

- Developing countries are investing in mineral exploration, increasing machinery deployment.

- Rising demand for metals and minerals is driving long-term market stability.

- Advanced undercarriage technologies improve mining equipment performance and longevity.

Technological Advancements Enhancing Market Expansion

- Innovations in materials like high-strength steel and reinforced rubber improve durability.

- IoT integration in undercarriage systems enhances predictive maintenance and reduces downtime.

- Advanced manufacturing techniques enable production of lightweight yet robust components.

- Automation in component design increases efficiency and reduces operational costs.

- AI-driven diagnostics improve wear and tear monitoring in undercarriage parts.

Aftermarket Services Contributing to Market Growth

- Regular replacement of undercarriage components creates a strong aftermarket demand.

- Equipment rental companies rely on high-quality replacement parts for maintenance.

- Cost-effective refurbishment of undercarriage systems boosts market revenue.

- Increasing use of track-based machinery in multiple industries expands aftermarket opportunities.

- Manufacturers are providing extended warranty services to increase component lifespan.

Growing Demand for Agriculture and Forestry Equipment

- Tractors and harvesters require durable undercarriage systems for different terrains.

- Rising mechanization in agriculture boosts demand for track-based machinery.

- Forestry applications need robust undercarriage components for rough landscapes.

- Technological advancements in agricultural machinery increase component efficiency.

- Sustainable farming practices promote the use of efficient and long-lasting equipment.

Regional Market Growth Insights

- North America: Increased infrastructure investments and technological innovations are driving growth.

- Europe: Stricter environmental regulations encourage the adoption of advanced undercarriage components.

- Asia-Pacific: Rapid urbanization and industrialization fuel high demand for construction and mining machinery.

- Latin America: Growing mining activities and agriculture mechanization contribute to market expansion.

- Middle East & Africa: Infrastructure development projects boost demand for heavy machinery undercarriage parts.

Competitive Landscape and Market Strategies

- Key players focus on R&D to enhance product durability and efficiency.

- Companies are expanding their global presence through mergers and acquisitions.

- Strategic collaborations help in technology sharing and production cost reduction.

- Sustainable manufacturing processes are gaining traction among leading companies.

- Market players are adopting smart tracking technologies for real-time component monitoring.

Challenges Affecting Market Growth

- High raw material costs impact overall component pricing.

- Frequent wear and tear lead to high maintenance expenses for end-users.

- Economic downturns may affect heavy machinery sales and undercarriage component demand.

- Stricter environmental regulations require sustainable manufacturing solutions.

- Counterfeit undercarriage parts pose challenges for original manufacturers.

Future Trends and Market Outlook

- Increasing use of electric and hybrid machinery will reshape undercarriage component demand.

- AI-based predictive maintenance solutions will optimize component lifespan and performance.

- Lightweight materials will gain popularity for enhancing equipment efficiency.

- Emerging markets will drive substantial growth in construction and mining machinery.

- Sustainable production techniques will become a priority for industry leaders.