Introduction

High-Density Polyethylene (HDPE) sheets are an essential material used across various industries due to their remarkable properties and versatility. As a premier manufacturer of flexible packaging products, Singhal Industries is at the forefront of delivering high-quality HDPE sheets tailored to meet diverse industrial needs. This blog will explore the characteristics, benefits, and wide-ranging applications of HDPE sheets, underscoring why they are a preferred choice for numerous applications.

What are HDPE Sheets?

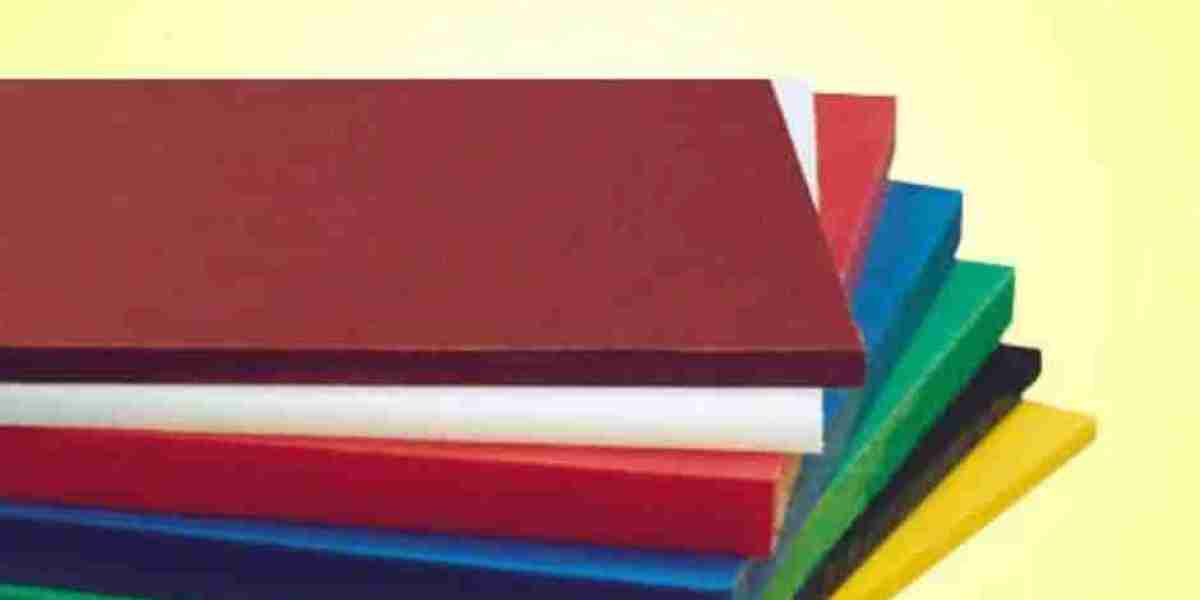

HDPE sheets are made from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. These sheets are lightweight yet incredibly strong, offering excellent resistance to impact, chemicals, and moisture. Available in various thicknesses, sizes, and colors, HDPE sheets can be customized to suit specific requirements, making them ideal for a broad range of industrial and commercial applications.

Key Properties of HDPE Sheets

- Durability: HDPE sheets are known for their exceptional durability, capable of withstanding heavy use and harsh environmental conditions.

- Chemical Resistance: They resist a wide variety of chemicals, including acids, bases, and solvents, making them suitable for many industrial applications.

- Moisture Resistance: HDPE sheets do not absorb moisture, which prevents warping and swelling, ensuring long-term performance.

- UV Resistance: These sheets can be formulated to resist UV radiation, making them suitable for outdoor use without significant degradation over time.

- Impact Resistance: The high impact resistance of HDPE sheets ensures they can handle heavy loads and impacts without cracking or breaking.

- Lightweight: Despite their strength, HDPE sheets are lightweight, making them easy to handle, transport, and install.

- Flexibility: HDPE sheets are flexible and can be easily cut, shaped, and welded to meet specific design and functional requirements.

Applications of HDPE Sheets

1. Construction

HDPE sheets are widely used in the construction industry for various purposes. They serve as liners for water tanks and ponds, protective barriers, and vapor barriers. Their moisture resistance and durability make them ideal for use in foundations and as protection against ground moisture.

2. Agricultural

In agriculture, HDPE sheets are used for greenhouse construction, irrigation systems, and storage bins. Their resistance to chemicals and weather conditions ensures that they provide long-lasting performance in demanding agricultural environments.

3. Industrial

HDPE sheets are employed in industrial settings for fabricating equipment parts, conveyor systems, and chemical tanks. Their chemical resistance and durability make them suitable for environments where exposure to harsh chemicals is common.

4. Packaging

HDPE sheets are used in the packaging industry for creating containers, pallets, and protective packaging materials. Their strength and impact resistance ensure that products are safely stored and transported.

5. Marine

Marine applications benefit from HDPE sheets due to their resistance to saltwater and UV radiation. They are used for constructing docks, boats, and marine fenders, providing a reliable and durable solution for marine environments.

6. Signage

The signage industry uses HDPE sheets for creating durable signs and displays. Their ease of fabrication and weather resistance make them suitable for both indoor and outdoor signage applications.

7. Recreational

HDPE sheets are used in recreational facilities for playground equipment, skateboarding ramps, and outdoor furniture. Their durability and safety properties ensure long-lasting and safe recreational structures.

Benefits of Using HDPE Sheets

1. Long-Term Performance

HDPE sheets offer excellent long-term performance due to their resistance to wear and environmental factors. They maintain their structural integrity over time, reducing the need for frequent replacements.

2. Cost-Effectiveness

The durability and low maintenance requirements of HDPE sheets make them a cost-effective solution for many applications. Their longevity ensures a good return on investment.

3. Environmental Impact

HDPE sheets are recyclable, contributing to sustainability efforts. Singhal Industries is committed to eco-friendly practices, ensuring that our HDPE sheets are produced and used in a manner that minimizes environmental impact.

4. Versatility

The versatility of Hdpe sheets Suppliers allows them to be used in a wide range of applications. Their ability to be customized in terms of size, thickness, and color ensures that they meet specific project requirements.

5. Safety

HDPE sheets are safe for use in various applications. They do not leach harmful chemicals, making them suitable for applications involving food and water contact.

Why Choose Singhal Industries for HDPE Sheets?

1. High-Quality Products

Singhal Industries is dedicated to producing high-quality HDPE sheets that meet stringent industry standards. Our products are known for their reliability, durability, and exceptional performance.

2. Customization Options

We offer a range of customization options for HDPE sheets, including different sizes, thicknesses, and colors. Our team works closely with clients to ensure that our products meet their specific needs.

3. Sustainability Commitment

Singhal Industries is committed to sustainability. Our HDPE sheets are produced using eco-friendly processes, and we strive to minimize our environmental footprint through recycling and responsible manufacturing practices.

4. Exceptional Customer Service

Our team of experts is always ready to assist clients in selecting the right HDPE sheets for their applications. We pride ourselves on providing exceptional customer service and ensuring complete client satisfaction.

Innovations in HDPE Sheet Technology

At Singhal Industries, we are continuously innovating to enhance the properties and performance of our Hdpe sheets 4x8. Recent advancements include the development of sheets with improved UV resistance, higher impact strength, and enhanced chemical resistance. These innovations ensure that our HDPE sheets remain at the cutting edge of material technology, providing reliable solutions for modern industrial challenges.

Case Studies: Success Stories with HDPE Sheets

1. Construction Project

A construction company partnered with Singhal Industries to supply HDPE sheets for lining water tanks and creating vapor barriers. The HDPE sheets provided excellent moisture resistance and durability, ensuring the success of the project and enhancing the longevity of the structures.

2. Agricultural Application

An agricultural business required HDPE sheets for constructing greenhouse structures and irrigation systems. Singhal Industries provided high-quality HDPE sheets that withstood harsh weather conditions and chemical exposure, resulting in improved crop yields and operational efficiency.

Environmental Impact of HDPE Sheets

Singhal Industries is dedicated to reducing the environmental impact of our products. Our Hdpe sheet supplier are manufactured using sustainable practices and are fully recyclable. We encourage our customers to recycle HDPE sheets at the end of their lifecycle, supporting environmental sustainability and reducing waste.

Conclusion

HDPE sheets offer a versatile, durable, and reliable solution for a wide range of industrial and commercial applications. From construction and agriculture to packaging and marine applications, these sheets provide exceptional performance and value. Singhal Industries is proud to be a leading manufacturer of high-quality HDPE sheets, delivering innovative solutions that meet the diverse needs of our customers.

When you choose Singhal Industries for your HDPE sheet needs, you are choosing a trusted partner committed to quality, sustainability, and exceptional customer service. Explore the benefits of HDPE sheets and discover why Singhal Industries is the preferred choice for businesses across various industries.

FAQS

1. What are HDPE sheets made of?

Answer: HDPE sheets are made from High-Density Polyethylene, a thermoplastic polymer known for its high strength-to-density ratio, offering durability and versatility for various applications.

2. What industries commonly use HDPE sheets?

Answer: HDPE sheets are used in numerous industries, including construction, agriculture, packaging, marine, signage, and recreational facilities, due to their strength, chemical resistance, and moisture resistance.

3. Can HDPE sheets be customized?

Answer: Yes, HDPE sheets can be customized in terms of size, thickness, color, and even specific properties like UV resistance to meet the unique needs of different projects and applications.

4. Are HDPE sheets environmentally friendly?

Answer: HDPE sheets are recyclable, which helps reduce their environmental footprint. Singhal Industries is committed to sustainability, ensuring that their HDPE sheets are produced using eco-friendly processes.

5. Why choose Singhal Industries for HDPE sheets?

Answer: Singhal Industries offers high-quality, customizable HDPE sheets with a commitment to sustainability and exceptional customer service, making them a reliable choice for various industrial and commercial needs.