Engineering Plastics Market Set to Redefine Industrial Performance with Unprecedented Growth and Innovation

The Engineering Plastics Market Growth is poised for significant expansion over the coming years, driven by rapid technological innovation, surging demand across critical sectors, and a strong focus on sustainable, high-performance materials. As industries worldwide seek advanced solutions to replace traditional materials, engineering plastics are emerging as a crucial component in applications that demand superior mechanical, thermal, and chemical properties.

Request Sample Link for More Details:https://www.maximizemarketresearch.com/request-sample/80012/

Market Estimation & Definition

Engineering plastics represent a specialized class of high-performance polymers engineered to meet stringent industrial demands. Unlike commodity plastics, these materials are designed to endure extreme operating conditions while delivering excellent performance, making them ideal for use in automotive, aerospace, electronics, medical devices, and various industrial applications. Their ability to offer enhanced durability, dimensional stability, and resistance to heat and chemicals makes engineering plastics a preferred alternative to metals and ceramics in many high-tech and safety-critical applications.

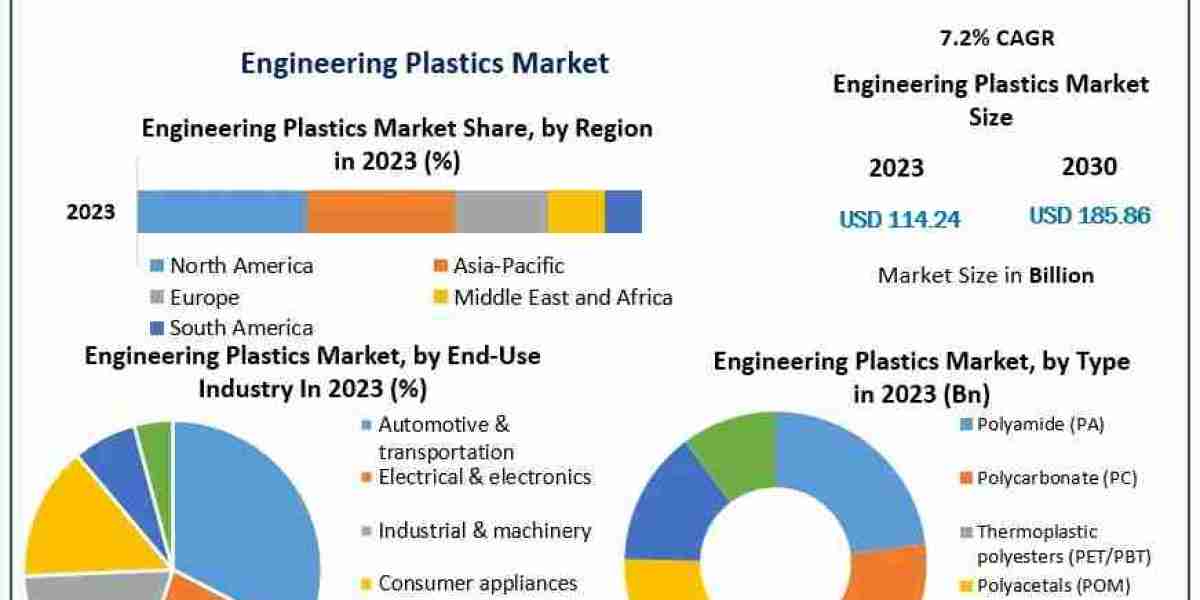

Current market analyses suggest that the global engineering plastics market is valued in the multi-billion-dollar range, with robust growth expected over the next decade. This expansion is underpinned by increased investments in research and development (R&D) that are driving continuous improvements in polymer formulations, processing techniques, and sustainable production practices. As industries strive for lightweight and energy-efficient solutions, engineering plastics are set to become even more integral to modern manufacturing processes.

Market Growth Drivers & Opportunities

The burgeoning growth of the engineering plastics market is attributed to several key drivers and opportunities:

Technological Advancements and Research & Development:

Breakthroughs in polymer science have led to the development of new engineering plastics with superior properties such as high-temperature resistance, exceptional mechanical strength, and excellent chemical stability. Significant investments in R&D are enabling manufacturers to innovate and tailor materials for specific applications, ensuring that products meet increasingly demanding performance criteria.

Automotive Sector Transformation:

The automotive industry is undergoing a transformation as automakers focus on reducing vehicle weight, enhancing fuel efficiency, and lowering emissions. Engineering plastics are being increasingly adopted in various automotive components—ranging from under-the-hood parts and interior trims to structural components—thereby reducing reliance on heavier metal parts. This shift towards lightweight materials is a major growth driver for the engineering plastics market.

Aerospace & Defense Applications:

In aerospace, the need for materials that combine high strength-to-weight ratios with durability under extreme conditions has led to the increased use of engineering plastics in both commercial and military applications. Their resistance to high temperatures, chemicals, and dynamic stresses makes them ideal for precision components, contributing to improved aircraft performance and fuel efficiency.

Expansion in Electronics & Medical Devices:

Engineering plastics are critical to the electronics industry due to their excellent insulating properties and dimensional stability. They are widely used in the manufacture of electronic housings, circuit boards, and connectors. In the medical devices sector, their biocompatibility, sterilization capability, and longevity are driving innovations in the production of surgical instruments, diagnostic equipment, and other critical healthcare products.

Sustainability and Environmental Considerations:

With global environmental regulations becoming increasingly stringent, manufacturers are prioritizing the development of sustainable materials. Engineering plastics that can be recycled or derived from bio-based sources are gaining momentum as companies strive to reduce their carbon footprints. This eco-conscious trend not only meets regulatory requirements but also appeals to environmentally aware consumers and businesses.

Infrastructure Development and Industrial Expansion:

Rapid industrialization and infrastructure development, particularly in emerging economies, are driving demand for advanced materials. As construction and manufacturing sectors expand, the need for reliable, high-performance polymers is rising, further propelling the growth of the engineering plastics market.

Get to Know More About This Market Study:https://www.maximizemarketresearch.com/market-report/global-engineering-plastics-market/80012/

Segmentation Analysis

The engineering plastics market is highly diversified, and its segmentation provides insights into the variety of applications and product categories that are fueling growth:

By Product Type:

Polyamide (PA):

Recognized for its high mechanical strength, thermal stability, and excellent wear resistance, polyamide is widely used in automotive components, electrical systems, and consumer goods. Its versatility in processing makes it a top choice for injection molding and extrusion applications.

Polyethylene Terephthalate (PET):

PET is celebrated for its clarity, strength, and barrier properties. It is extensively used in packaging, electronics, and automotive sectors, especially where transparency and durability are key.

Request Sample Link for More Details:https://www.maximizemarketresearch.com/request-sample/80012/

Polyphenylene Sulfide (PPS):

PPS offers outstanding chemical resistance and thermal stability, making it ideal for high-performance applications in electronics, automotive under-the-hood parts, and industrial components.

Polycarbonate (PC):

Known for its impact resistance and high optical clarity, polycarbonate is commonly utilized in consumer electronics, medical devices, and automotive parts, providing a balance of durability and design flexibility.

Other Engineering Plastics:

This segment includes specialty polymers developed for niche applications requiring enhanced electrical insulation, flame retardancy, or superior barrier properties. These materials are increasingly used in high-tech electronics, aerospace components, and specialized industrial products.

By End-Use Industry:

Automotive:

Engineering plastics are vital in reducing vehicle weight and improving fuel efficiency. Their application spans structural parts, under-the-hood components, and interior elements.

Aerospace & Defense:

The aerospace sector relies on engineering plastics for components that require a high strength-to-weight ratio and exceptional durability under extreme conditions.

Electronics & Electrical:

These materials are indispensable in manufacturing electronic housings, connectors, and circuit boards, where thermal stability and insulation are paramount.

Medical Devices:

In healthcare, the biocompatibility and sterilization compatibility of engineering plastics are critical for producing safe and reliable medical instruments and devices.

Industrial & Consumer Applications:

A broad range of industrial applications—from machinery components to consumer appliances—benefit from the robustness and longevity of engineering plastics.

By Geography:

The market is segmented into key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region offers unique opportunities driven by local industrialization trends, regulatory frameworks, and technological adoption.

Country-Level Analysis

United States:

The U.S. engineering plastics market is characterized by a strong industrial base, significant investments in R&D, and a well-established automotive and aerospace industry. The focus on lightweight materials to enhance fuel efficiency and reduce emissions in automotive applications has accelerated the adoption of engineering plastics. Additionally, the U.S. is a hub for technological innovation, with numerous research institutions and companies driving advancements in polymer science. This environment has created favorable conditions for the rapid growth of the engineering plastics market, positioning the country as a leader in both production and innovation.

Germany:

Germany’s reputation for engineering excellence and precision manufacturing makes it a key market for engineering plastics. The country’s automotive and industrial sectors are at the forefront of adopting advanced materials to improve performance and sustainability. German manufacturers are known for their rigorous quality standards and commitment to research and development, which has spurred the creation of high-performance engineering plastics tailored to meet specific industry needs. Furthermore, Germany’s focus on environmental sustainability is leading to increased investment in eco-friendly production processes, further strengthening its position in the global market.

Competitive Analysis

The competitive landscape in the engineering plastics market is robust, featuring a mix of global giants and specialized regional players. These companies are continuously innovating to enhance the performance, sustainability, and cost-effectiveness of their products. Leading industry participants include:

BASF SE:

As one of the world’s foremost chemical companies, BASF SE offers an extensive portfolio of engineering plastics used across various sectors. The company’s significant investments in R&D and its focus on sustainable production practices have cemented its status as a market leader.

Covestro AG:

Covestro AG is renowned for its cutting-edge polymer solutions and high-performance engineering plastics. With a strong emphasis on innovation, the company is continuously developing materials that deliver superior thermal, mechanical, and chemical resistance, catering to industries such as automotive and electronics.

SABIC (Saudi Basic Industries Corporation):

SABIC is a dominant player in the global petrochemicals and plastics markets, providing a wide range of engineering plastics that serve critical applications in automotive, industrial, and consumer markets. Their strategic investments in expanding production capacity and technological capabilities are key drivers of their market success.

DuPont:

With a long history of innovation, DuPont continues to be at the forefront of developing advanced materials. Their engineering plastics are designed to meet the rigorous demands of industries such as aerospace, automotive, and healthcare, emphasizing performance and reliability.

Celanese Corporation:

Known for its high-quality engineering plastics, Celanese Corporation supplies materials that deliver exceptional performance in high-stress environments. Their focus on cost-effective production and technological advancements ensures a strong competitive edge in the market.

These companies, among others, are investing in new technologies and forging strategic partnerships to drive innovation and expand their global footprint. The ongoing pursuit of sustainable and high-performance materials is reshaping the competitive dynamics, ensuring that the market remains both dynamic and resilient in the face of evolving industrial demands.

Press Release Conclusion

The global engineering plastics market is on a transformative trajectory, underpinned by rapid technological advancements, expanding applications, and an ever-growing demand for sustainable and high-performance materials. Industries across the automotive, aerospace, electronics, medical devices, and industrial sectors are increasingly relying on engineering plastics to achieve greater efficiency, durability, and performance in their products.

In the United States, a strong emphasis on innovation and lightweight material applications continues to drive the market forward, while Germany’s commitment to engineering excellence and sustainability fosters advanced material development and rigorous quality standards. These regional strengths are complemented by global competitive dynamics, where leading players are continuously investing in R&D and strategic partnerships to push the boundaries of what engineering plastics can achieve.

For additional insights, visit:

Polystyrene Foam Market https://www.maximizemarketresearch.com/market-report/global-polystyrene-foam-marke/99916/

Medical Foam Market https://www.maximizemarketresearch.com/market-report/global-medical-foam-market/96794/

Structural Adhesives Market https://www.maximizemarketresearch.com/market-report/global-structural-adhesives-market/33818/

About Maximize Market Research:

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Maximize Market Research:

MAXIMIZE MARKET RESEARCH PVT. LTD.

⮝ 3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

✆ +91 9607365656

? sales@maximizemarketresearch.com

? www.maximizemarketresearch.com