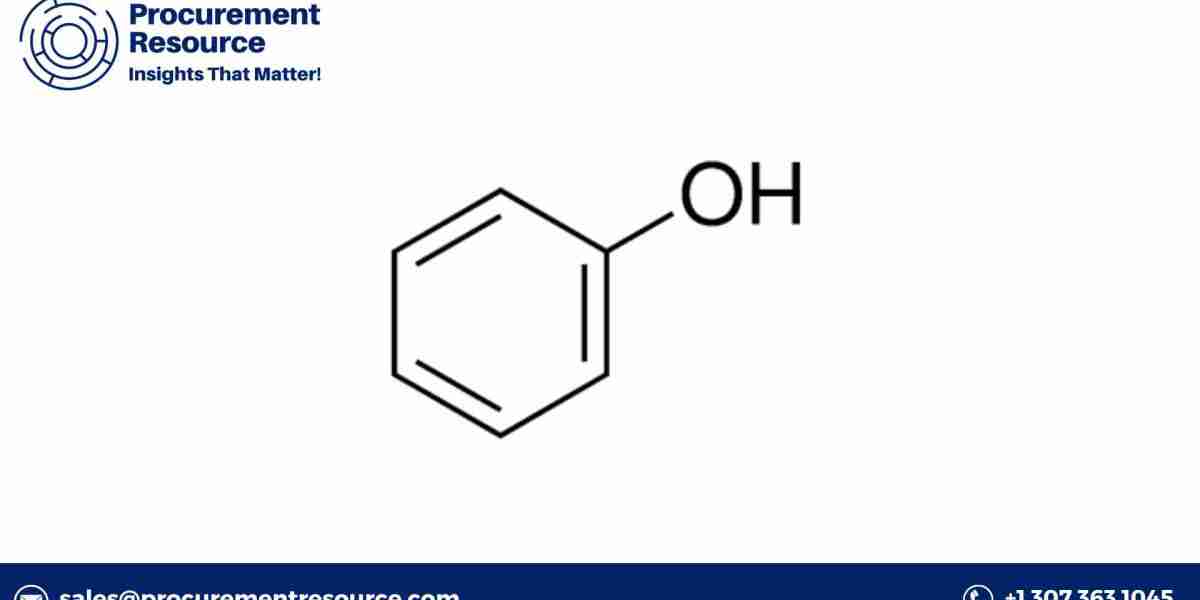

Phenol, a versatile organic compound, serves as a crucial raw material in various industrial applications, including the production of plastics, resins, and pharmaceuticals. A comprehensive Phenol Manufacturing Plant Project Report is essential for businesses and investors aiming to navigate this complex and competitive sector. This article provides an exhaustive overview of phenol manufacturing, covering cost models, leading manufacturers, feedstocks, market dynamics, manufacturing processes, and key insights, alongside the value of expert procurement resource.

Market Overview of Phenol

Phenol’s significance stems from its applications in multiple industries. It is widely used in manufacturing polycarbonate plastics, epoxy resins, and bisphenol A (BPA). With the rise in demand for advanced plastics and resins, phenol’s market trajectory continues to ascend.

Request Your Free Sample Report - https://www.procurementresource.com/reports/phenol-manufacturing-plant-project-report/request-sample

Market Drivers

Growing Demand in Construction and Automotive Sectors: Phenol-based products, such as laminates and adhesives, are integral to these industries.

Advancements in Electronics: Polycarbonate plastics derived from phenol are indispensable in electronic devices.

Rise in Pharmaceuticals: Phenol is a precursor for several drugs, enhancing its demand in the healthcare sector.

Expansion of Emerging Markets: Rapid industrialization in regions like Asia-Pacific boosts phenol consumption.

Phenol Manufacturing Process

Key Feedstocks

The primary raw materials for phenol production include:

Benzene: A key aromatic hydrocarbon.

Propylene: Used in the cumene process.

Oxygen and Catalysts: Crucial for oxidation reactions.

Manufacturing Process Outline

Cumene Process:

Benzene reacts with propylene to form cumene.

Cumene undergoes oxidation to produce cumene hydroperoxide.

This intermediate is cleaved to yield phenol and acetone.

Alternative Methods:

Toluene Oxidation: Converts toluene to phenol via a multi-step process.

Raschig Process: Employs chlorobenzene and sodium hydroxide.

Each method has its economic and environmental implications, with the cumene process being the most prevalent due to its cost-effectiveness and efficiency.

Cost Model of Phenol Manufacturing

A detailed cost model in the Phenol Manufacturing Plant Project Report includes:

Capital Expenditure (CAPEX)

Plant Setup: Costs related to land acquisition, construction, and installation of machinery.

Technology Licensing: Fees for patented processes or proprietary technologies.

Utilities: Establishing electricity, water, and other utilities.

Operating Expenditure (OPEX)

Raw Material Costs: Benzene and propylene are significant contributors.

Labor Costs: Skilled labor for operations and maintenance.

Energy Consumption: Electricity and heat requirements.

Environmental Compliance: Adhering to emission and waste disposal regulations.

Economic Considerations

Cost fluctuations in feedstocks like benzene and propylene.

Regional factors such as proximity to raw material suppliers and end markets.

Top Manufacturers in the Phenol Industry

Global Leaders

INEOS Phenol:

Largest global producer with state-of-the-art facilities.

SABIC:

Focuses on innovation and sustainability.

Mitsui Chemicals:

Renowned for high-quality phenol production.

Regional Players

Asia-Pacific: Reliance Industries, LG Chem.

North America: Honeywell, Altivia.

Europe: BASF, CEPSA.

These companies leverage advanced technologies, economies of scale, and integrated supply chains to maintain their market positions.

Read Full Report With Table Of Contents: https://www.procurementresource.com/reports/phenol-manufacturing-plant-project-report/toc

Key Insights from the Phenol Manufacturing Plant Project Report

Sustainability Trends:

Increasing focus on green chemistry and reducing carbon footprints.

Development of bio-based phenol as an alternative.

Technological Innovations:

Advances in catalysts to enhance yield and efficiency.

Real-time monitoring systems for process optimization.

Market Opportunities:

Expansion in emerging economies.

Rising investments in downstream industries like plastics and resins.

Challenges:

Volatile raw material prices.

Stricter environmental regulations.

Role of Procurement Resource

Efficient procurement strategies are pivotal in phenol manufacturing. Procurement Resource offers valuable insights into market trends, cost analysis, and supplier evaluations, enabling businesses to make informed decisions. Their expertise in benchmarking and procurement analytics ensures optimal sourcing and cost savings.

A thorough understanding of the phenol manufacturing landscape is indispensable for stakeholders in this industry. The Phenol Manufacturing Plant Project Report provides a detailed roadmap, from cost structures to market dynamics and sustainability trends. Leveraging expert procurement resources and staying abreast of technological advancements can position businesses for long-term success in the phenol market.

For businesses and investors, this report is not merely a guideline but a strategic tool to navigate the intricacies of the phenol industry effectively.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA