Introduction to PC Hollow Sheets

PC hollow sheets, or polycarbonate hollow sheets, are a remarkable innovation in the field of construction and design, characterized by their unique combination of strength, lightweight nature, and clarity. Polycarbonate (PC) as a material has gained immense popularity in various applications due to its high resistance to impact and thermal fluctuations. In India, the use of polycarbonate sheets has significantly increased across multiple sectors, including construction, agriculture, signage, and automotive industries. These sheets possess a unique hollow structure, which contributes to their exceptional insulating properties and reduced weight, making them a preferred choice for designers and architects aiming for sustainability and efficiency in their projects. This Pulkit Plastic Products delves into the features, applications, market dynamics, and environmental impact of PC hollow sheets, highlighting their growing significance in contemporary settings.

The Unique Characteristics of Polycarbonate Sheets

The most significant advantage of PC hollow sheets lies in their inherent characteristics. Made from polycarbonate, a high-performance thermoplastic, these sheets are known for their outstanding impact resistance, which can be up to 200 times greater than that of glass. This durability makes them an ideal choice for applications where safety and integrity are paramount. Furthermore, polycarbonate sheets are remarkably lightweight, about half the weight of glass, which simplifies transportation and installation processes.

In addition to their strength, polycarbonate sheets offer excellent thermal insulation properties. Their unique hollow structure serves as an effective barrier against temperature changes, making them suitable for buildings in varied climates. Moreover, they allow for the transmission of natural light while blocking harmful ultraviolet (UV) rays, creating an environment that supports natural light while protecting interiors and inhabitants.

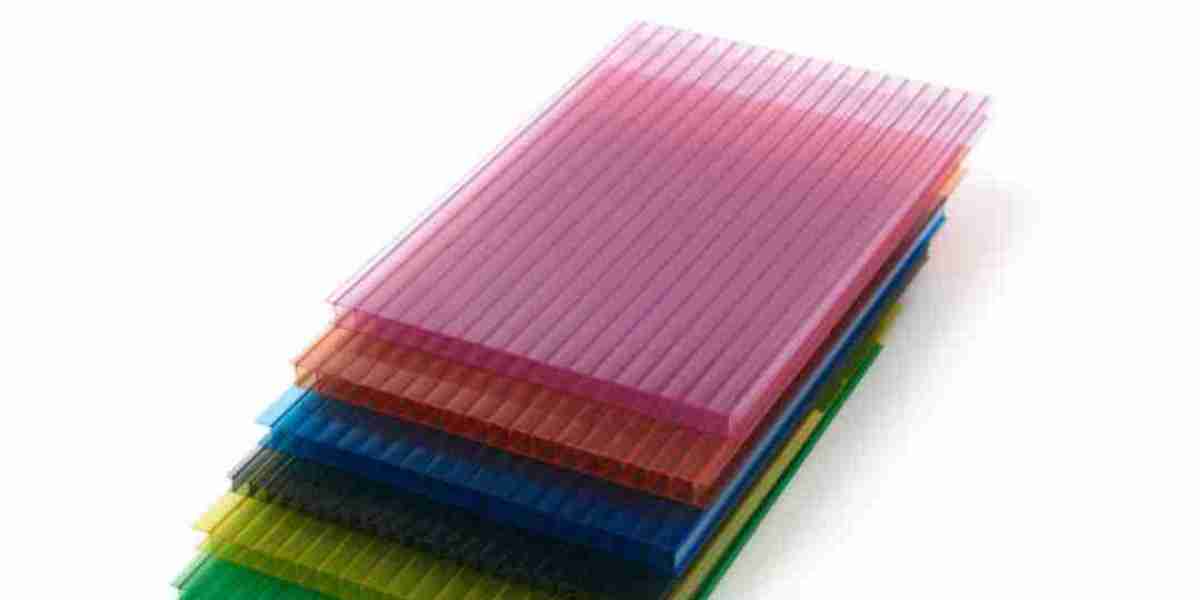

Another unique characteristic of PC hollow sheets is their versatility in terms of design and customization. Available in various colors, thicknesses, and finishes, these sheets can be tailored to meet specific project requirements. Whether for roofing, glazing, or signage applications, the aesthetic flexibility and functional integrity of polycarbonate sheets make them an asset in various design projects.

Applications of PC Hollow Sheets Across Industries

The PC hollow sheets are employed in a wide range of applications, showcasing their versatility and functionality across different sectors. In the construction industry, they are commonly used for roofing applications, particularly in commercial and residential buildings. Their ability to withstand extreme weather conditions and provide excellent thermal insulation makes them ideal for awnings, skylights, greenhouses, and patio covers.

In the agricultural sector, polycarbonate sheets serve as effective greenhouse materials. The insulating properties and UV resistance help create an optimal environment for plant growth while minimizing energy costs associated with heating or cooling. Farmers and horticulturists are increasingly recognizing the benefits of incorporating PC hollow sheets into greenhouse structures, as they contribute to higher yields and reduced resource consumption.

The signage industry has also adopted polycarbonate sheets for their lightweight, impact-resistant, and easy-to-fabricate characteristics. These sheets can be easily cut and shaped, making them ideal for illuminated signage, protective displays, and point-of-purchase materials. Their clarity and availability in various colors allow for creativity in design, which is essential for effective branding and communication.

In the automotive sector, polycarbonate sheets are utilized in applications ranging from headlight lenses to interior components. Their ability to withstand vibrations and exposure to the elements without deteriorating over time enhances the longevity and aesthetics of vehicles. With the automotive industry increasingly focusing on lightweight materials for improved fuel efficiency, polycarbonate sheets are becoming a staple.

The Growing Demand for PC Hollow Sheets in India

The demand for PC hollow sheets in India is experiencing a significant uptick due to various factors, including rapid urbanization, increased construction activities, and a growing focus on renewable energy solutions. As cities expand and development projects proliferate, the need for durable, efficient, and aesthetically satisfying building materials is more critical than ever.

Government initiatives aimed at promoting sustainable building practices have also propelled the growth of the polycarbonate sheets market. As more builders and developers seek eco-friendly solutions that adhere to green building standards, PC hollow sheets fit perfectly within these objectives by offering both utility and sustainability.

Additionally, the agricultural sector's shift towards advanced practices, including efficient greenhouse cultivation, has further stimulated demand for polycarbonate sheets. As farmers strive to optimize crop yield and minimize resource usage, the benefits of PC hollow sheets are increasingly recognized, leading to widespread adoption.

Moreover, rising awareness regarding energy efficiency and the need for sustainable materials drives eco-conscious consumers to opt for polycarbonate sheets. With more individuals prioritizing environmentally friendly choices in their building materials, the demand for PC hollow sheets is anticipated to continue on an upward trajectory.

Understanding the Pricing Dynamics of PC Hollow Sheets

The pricing of PC hollow sheets in India is influenced by several variables, each impacting production costs and market pricing strategies. The primary factor affecting these prices is the cost of raw materials, specifically polycarbonate resin, which is dependent on the global oil market and the availability of petroleum derivatives. Fluctuations in oil prices can significantly affect the overall cost of production for polycarbonate sheets.

In addition to raw material costs, production methods also play a crucial role in determining prices. Advanced manufacturing processes, including extrusion technology, can create high-quality polycarbonate sheets while optimizing resource consumption. Manufacturers that invest in innovative production techniques may benefit from reduced operational costs, potentially lowering their market prices.

Moreover, market dynamics, including competition among suppliers, influence pricing strategies. As the demand for polycarbonate sheets continues to grow, new players may enter the market, leading to competitive pricing. This competition can yield better options for consumers and help stabilize prices over time.

Geographical factors also contribute to pricing variations in different regions of India. Transportation costs, regional demand fluctuations, and local suppliers’ pricing strategies can all impact the final cost of PC hollow sheets. However, with increasing standardization in manufacturing and distribution channels, more consistent pricing is expected across various markets.

Installation and Maintenance of PC Hollow Sheets

Installing Polycarbonate sheet price requires careful consideration of several factors to ensure optimal performance and longevity. One of the main benefits of using polycarbonate sheets is their lightweight nature, which not only facilitates easier transportation but also allows for straightforward installation. Nevertheless, adhering to best practices during installation is essential to maximize their benefits.

Proper cutting and fitting are critical in ensuring that the sheets perform well in their intended applications. It is advisable to use the right tools when cutting polycarbonate sheets to achieve clean edges and prevent cracking. For roofing and similar installations, employing a modular framing system can help enhance the structural integrity and ease of assembly.

Maintaining PC hollow sheets is relatively low-maintenance compared to other materials, thanks to their durability and resistance to deterioration. Regular cleaning with mild soap and water is generally sufficient to keep the sheets clear and free from dirt or grime. Ensuring that the edges are properly sealed is also crucial to prevent water infiltration and prolong the lifespan of the sheets.

During installation, careful attention to detail can make a significant difference in the performance and longevity of polycarbonate sheets. Implementing suitable weather protection measures, using appropriate fasteners, and sealing joints properly can prevent common issues such as leaks or temperature-related expansions and contractions.

Environmental Considerations and Sustainability

The environmental impact of PC hollow sheets is a critical topic, particularly in today's world where sustainability is paramount. Polycarbonate sheets possess several eco-friendly attributes, including their recyclability and durability. At the end of their life cycle, these sheets can be reprocessed and utilized in the production of new plastic products, resulting in reduced waste.

Moreover, the energy efficiency provided by polycarbonate sheets also contributes positively to environmental sustainability. Their thermal insulating properties help reduce energy consumption in buildings by minimizing heating and cooling requirements. This not only lowers energy bills but also decreases the carbon footprint of a property, aligning with the global movement toward energy efficiency.

In India, where rapid urbanization poses significant environmental challenges, incorporating sustainable materials like polycarbonate sheets becomes essential to creating a greener future. Many manufacturers are now adopting sustainable practices in their production processes, focusing on minimizing resource usage and waste generation.

The ongoing innovations in the field of materials science aim to enhance the sustainability and performance properties of polycarbonate sheets. Research into bio-based alternatives and greener production methods could pave the way for even more environmentally friendly solutions, aligning with global sustainability goals.

Conclusion: The Bright Future of PC Hollow Sheets

The versatility and practicality of Polycarbonate sheet near me are leading them to become a cornerstone material in various applications across India and beyond. From construction and agriculture to signage and automotive industries, the adaptability of polycarbonate sheets is impressive, making them an excellent choice for modern design and functionality.

As the demand for sustainable materials continues to rise, PC hollow sheets are likely to remain at the forefront of many industries, offering advantages in durability, energy efficiency, and aesthetic flexibility. Additionally, innovations in manufacturing processes and design capabilities promise to further enhance their appeal.

Overall, the future landscape for PC hollow sheets appears bright, with opportunities for growth stemming from increased urbanization, infrastructural development, and growing environmental awareness. For architects, builders, and consumers seeking durable and sustainable materials, polycarbonate sheets offer a compelling solution that aligns with modern building practices and ecological consciousness.

Frequently Asked Questions

1. What are the primary benefits of using PC hollow sheets?

PC hollow sheets provide several advantages, including high impact resistance, lightweight nature, excellent thermal insulation, UV protection, and design flexibility. They are ideal for various applications, from construction to agriculture.

2. Where are polycarbonate sheets commonly used in India?

Polycarbonate sheets are commonly utilized in sectors such as construction (for roofing and glazing), agriculture (for greenhouses), signage (for displays and illuminated signs), and automotive manufacturing (for headlight lenses and other components).

3. How should PC hollow sheets be maintained?

Maintaining PC hollow sheets involves regular cleaning with mild soap and water to remove dirt and grime. It is also crucial to properly seal edges during installation to prevent infiltration and properly care for the joints to ensure longevity.

4. Are polycarbonate sheets recyclable?

Yes, polycarbonate sheets are recyclable and can be processed into new products once they reach the end of their life cycle. This characteristic makes them an environmentally friendly choice compared to many traditional materials.