The vinyl flooring plasticizers market plays a pivotal role in enhancing the performance and durability of vinyl flooring products. These plasticizers are added to vinyl compounds to make them more flexible and adaptable for various applications. However, despite the substantial growth potential, several challenges hinder the market’s progress. By understanding these barriers, stakeholders can better navigate and address the limitations.

One of the most significant constraints is the environmental impact of certain plasticizers used in vinyl flooring. Some of the chemicals used, particularly phthalates, have been associated with health and environmental risks. Regulatory bodies across various regions are becoming more stringent in terms of chemical composition regulations, pushing manufacturers to seek alternatives. This is a major concern, as switching to safer alternatives may lead to higher production costs and adjustments in manufacturing processes.

Another significant challenge in the vinyl flooring plasticizers market is the fluctuating cost of raw materials. The price of petroleum-based products, which are essential in producing certain plasticizers, is highly volatile. These price fluctuations create an unstable cost structure, making it difficult for manufacturers to predict their expenses and, consequently, plan their pricing strategies effectively. Additionally, supply chain disruptions, particularly in regions affected by geopolitical tensions or natural disasters, exacerbate these challenges.

The increasing demand for eco-friendly products has also created a shift in consumer preferences. With rising awareness about environmental sustainability, consumers are increasingly seeking products that are free from harmful chemicals and made from renewable resources. Vinyl flooring, although durable and versatile, is often viewed as less environmentally friendly compared to other flooring options, such as bamboo or cork. Manufacturers in the vinyl flooring plasticizers market are facing the challenge of addressing this shift while balancing performance, cost, and environmental impact.

Moreover, competition from alternative materials is a growing concern. As the vinyl flooring market faces increasing environmental scrutiny, other types of flooring materials, such as ceramic tiles, engineered wood, and even recycled materials, are gaining popularity. These alternatives are often perceived as more sustainable and are increasingly seen as viable substitutes for vinyl flooring in various applications. As such, the vinyl flooring plasticizers market must not only innovate to meet regulatory and consumer demands but also counter the threat of competitors offering more sustainable or cost-effective solutions.

Technological advancements also present both opportunities and challenges. While innovation in plasticizer production and vinyl flooring manufacturing is key to improving product quality and sustainability, it also requires significant investment. Smaller manufacturers or companies with limited resources may struggle to keep up with the technological advancements required to meet new regulatory standards and consumer expectations. This technological gap could result in market consolidation, with larger companies dominating the sector, potentially stifling innovation.

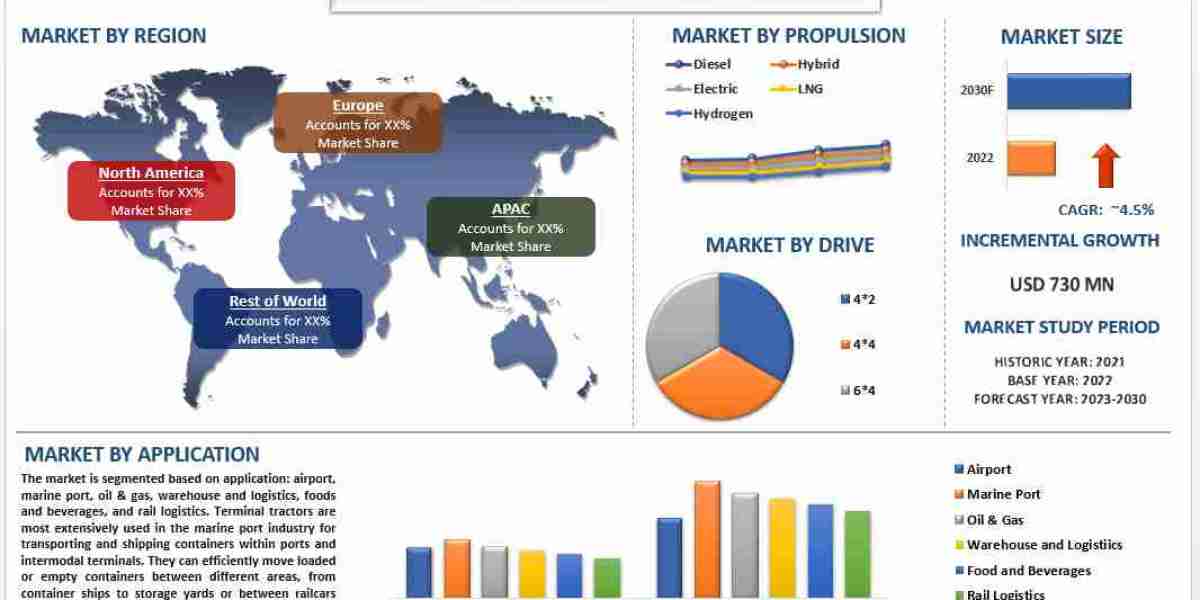

Market expansion in emerging economies, while offering growth potential, also presents challenges. Countries in Asia-Pacific, Africa, and Latin America are seeing rising demand for vinyl flooring due to urbanization and industrialization. However, these regions often face challenges such as lack of infrastructure, regulatory uncertainty, and limited access to high-quality raw materials. The vinyl flooring plasticizers market may struggle to penetrate these regions unless companies can adapt to local conditions and navigate complex regulatory landscapes effectively.

Lastly, the global push for recycling and circular economy practices presents both a challenge and an opportunity. The vinyl flooring industry generates a significant amount of waste, and there is increasing pressure to find sustainable ways to recycle or repurpose vinyl flooring materials. Companies in the vinyl flooring plasticizers market must find solutions that not only make the plasticizers themselves more sustainable but also facilitate the recycling of flooring materials, ensuring that the products remain viable in a circular economy.

In conclusion, while the vinyl flooring plasticizers market offers considerable growth potential, several barriers need to be addressed for it to achieve long-term success. Environmental concerns, regulatory pressures, competition from alternative materials, and the need for technological innovation are key challenges that must be overcome. By focusing on sustainability, innovation, and adapting to global trends, stakeholders in the vinyl flooring plasticizers market can pave the way for a more successful and sustainable future.