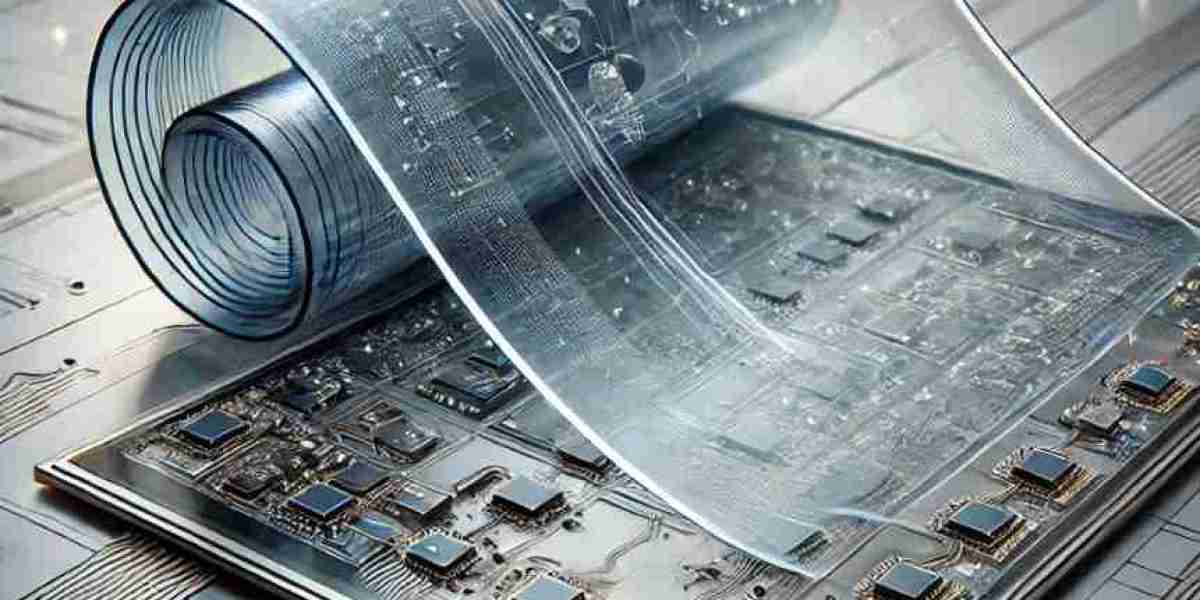

The Thin-Film Encapsulation (TFE) market has gained considerable attention in recent years due to its promising applications in the fields of electronics, photovoltaics, and flexible displays. Thin-film encapsulation technology is primarily used to protect sensitive components from environmental factors, improving their longevity and performance. However, despite its potential, several inhibitors continue to limit the growth and overall market potential of TFE technology. Understanding these factors is crucial for stakeholders looking to navigate the market and invest in its future.

High Manufacturing Costs

One of the primary inhibitors of growth in the Thin-Film Encapsulation (TFE) market is the high cost of manufacturing. The production of thin-film encapsulation layers requires highly advanced materials and complex processes, such as vacuum deposition, chemical vapor deposition, and atomic layer deposition. These methods are resource-intensive and expensive, leading to high upfront costs for manufacturers. This, in turn, limits the accessibility of TFE technology to smaller companies and increases the overall production cost for end-users, restricting the widespread adoption of thin-film encapsulation solutions.

Material Limitations

Another significant factor holding back the Thin-Film Encapsulation (TFE) market is the limitation of materials used in the process. While TFE typically relies on materials like organic polymers, inorganic films, and glass, the need for better barrier properties has created challenges. The materials available may not always meet the required standards for high-performance applications, such as those in flexible electronics or solar panels, where enhanced barrier protection is critical. In addition, the long-term stability of some materials used in TFE processes can be problematic, affecting the durability of encapsulated products. As technology advances, the quest for new materials with superior properties continues, but the lack of ideal materials hampers the full potential of the market.

Complexity in Integration with Existing Systems

Integrating Thin-Film Encapsulation (TFE) technology into existing manufacturing systems is another barrier to its widespread adoption. TFE processes often require specific environmental conditions and specialized equipment, which may not be readily available in current production lines. This integration complexity can increase the time and cost of transitioning to TFE technology for established industries. For manufacturers looking to implement TFE in their production systems, substantial upfront investment in new equipment and technology is often necessary. This makes the transition to TFE-based solutions challenging, especially for industries that already rely heavily on traditional packaging methods.

Reliability Concerns in Extreme Environments

Thin-film encapsulation is designed to protect sensitive electronics from environmental factors like moisture, oxygen, and UV radiation. However, in extreme conditions such as high temperatures, humidity, or harsh chemical environments, TFE technology may not always offer the level of protection needed. This limitation is particularly crucial for industries like aerospace, automotive, and industrial applications, where components are exposed to severe conditions. The current capabilities of TFE may not yet provide the necessary durability in these demanding environments, limiting the market’s potential in certain sectors.

Regulatory and Standardization Challenges

Another inhibitor affecting the growth of the Thin-Film Encapsulation (TFE) market is the lack of standardized regulations and industry guidelines. As a relatively new technology, TFE has yet to be governed by universally accepted standards, which leads to inconsistencies in quality and performance across different products and manufacturers. This lack of regulation can create confusion for companies looking to adopt TFE solutions and can delay the development of a more uniform global market. In addition, regulatory bodies are still assessing the long-term environmental impact of the materials used in TFE processes, which can further delay the widespread implementation of these technologies.

Challenges in Scaling Production

While thin-film encapsulation shows promise in small-scale applications, scaling up production to meet the demands of larger markets has proven challenging. The precision required in thin-film deposition techniques becomes more difficult to maintain as production volumes increase. The lack of scalability in existing TFE processes often results in higher costs, lower yields, and potential quality control issues. To overcome this barrier, manufacturers must develop more efficient and scalable TFE technologies that can meet the requirements of mass production without compromising performance or cost-effectiveness.

Conclusion

The Thin-Film Encapsulation (TFE) market holds immense potential across various industries, especially in electronics and renewable energy. However, challenges such as high manufacturing costs, material limitations, integration complexities, environmental reliability, regulatory hurdles, and scalability issues continue to limit its growth. By addressing these inhibitors and investing in advanced materials, new manufacturing techniques, and standardized regulations, the industry could unlock greater opportunities and expand the potential of TFE technology. As innovation continues, the market may overcome these challenges and reach new heights in the coming years.