The electrostatic discharge (ESD) packaging market is witnessing rapid penetration across diverse industries. As technology advances and electronic devices become an integral part of daily life, the demand for robust packaging solutions to safeguard sensitive components against electrostatic discharge is on the rise. This growth trajectory is significantly influenced by the expansion of the consumer electronics and automotive sectors, advancements in technology, and a growing awareness of the importance of product safety during transportation and storage.

Key Drivers of Market Growth

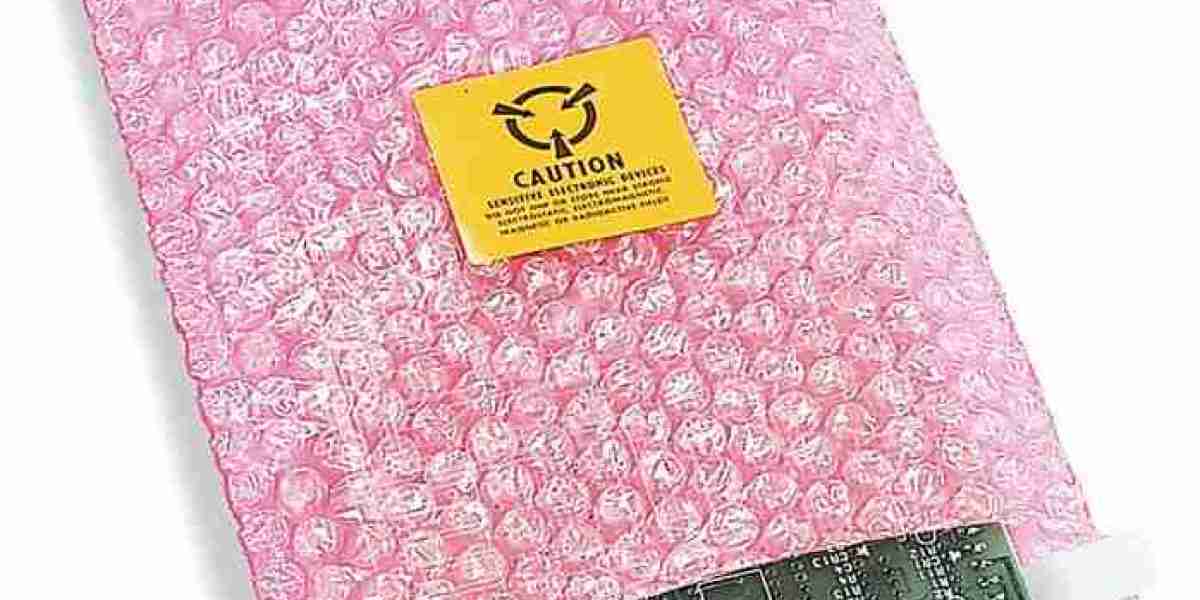

Increasing Demand in Electronics Manufacturing: The proliferation of smart devices, wearables, and other consumer electronics has propelled the need for ESD packaging solutions. These solutions prevent electrostatic damage during production, assembly, or shipping, ensuring product integrity.

Adoption in Automotive and Aerospace Industries: Modern vehicles and aerospace systems rely on electronic control units and other delicate components that require protection from static electricity. The adoption of ESD packaging in these industries has provided a substantial boost to market growth.

Stringent Regulations and Standards: Governments and industry bodies have introduced guidelines to minimize electrostatic damage in critical applications. Compliance with these regulations has necessitated the integration of high-performance ESD packaging materials.

Key Trends and Innovations

Use of Eco-Friendly Materials: Sustainability is becoming a top priority, leading to the adoption of biodegradable and recyclable materials in ESD packaging. This transition not only aligns with environmental goals but also broadens market acceptance.

Advancement in Conductive Packaging: Developments in conductive and anti-static materials are driving innovations in the sector, offering enhanced protective capabilities.

Integration with IoT and Smart Technologies: Some manufacturers are embedding sensors in ESD packaging to monitor environmental conditions like temperature and humidity. This added functionality provides valuable insights and an extra layer of assurance during transit.

Challenges in Market Penetration

Despite its potential, the ESD packaging market faces several challenges:

High Initial Investment Costs: The upfront costs of adopting advanced ESD packaging solutions can deter small and medium-sized enterprises (SMEs) from entering the market.

Lack of Awareness in Developing Regions: While demand is growing in developed economies, emerging markets often lack awareness and infrastructure, limiting adoption rates.

Strategies for Growth

Raising Awareness: Educational initiatives and workshops to demonstrate the benefits of ESD packaging can significantly enhance adoption.

Targeting Key Verticals: Prioritizing sectors like electronics, automotive, and healthcare where sensitive components are critical can optimize market penetration.

Cost Optimization: Research into cost-effective materials and production methods can make ESD packaging more accessible to a broader range of businesses.

Conclusion

The electrostatic discharge packaging market is set for significant growth, driven by technological advancements and an increasing emphasis on product safety. As industries prioritize minimizing damage to sensitive components, innovative ESD packaging solutions will continue to gain traction. To ensure sustained market penetration, stakeholders must overcome cost and awareness barriers while maintaining a focus on innovation and environmental sustainability.