The industrial flue gas treatment market has seen substantial growth due to increasing regulatory pressures and industrial needs to reduce emissions. A key factor influencing the market’s evolution is the dynamic pricing trends and the competitive landscape that define how treatment solutions are offered across various industries. This article explores the pricing trends, factors affecting costs, and the competitive environment in the industrial flue gas treatment market.

Pricing Trends in the Industrial Flue Gas Treatment Market

1. Cost of Advanced Technologies

The cost of industrial flue gas treatment systems varies based on the technology used. Advanced solutions such as carbon capture, utilization, and storage (CCUS) and selective catalytic reduction (SCR) systems tend to be more expensive due to their complexity and energy requirements. The increasing demand for these advanced technologies is pushing the pricing upwards, especially in industries with high emission levels.

Carbon Capture Technologies

Carbon capture and storage technologies, although expensive initially, are being prioritized due to their ability to mitigate CO2 emissions. The capital investment for these systems is significant, but ongoing research and development efforts are reducing their overall cost over time. This cost reduction is expected to make these technologies more accessible to industries globally.Filtration and Scrubbing Technologies

Filtration and scrubbing technologies, such as dry and wet scrubbers, remain more affordable alternatives to advanced carbon capture solutions. However, the prices of these systems also vary depending on the size of the installation, the type of industrial processes involved, and the required capacity. As industries increasingly adopt stricter emission control measures, the demand for these solutions is growing, leading to higher competition among manufacturers.

2. Impact of Raw Materials and Supply Chain

The cost of raw materials plays a significant role in determining the overall cost of flue gas treatment systems. The prices of materials used in constructing systems, such as metals and chemicals, have fluctuated in recent years due to supply chain disruptions, geopolitical tensions, and changes in demand.

Fluctuating Material Prices

The rising cost of raw materials can cause fluctuations in the pricing of treatment systems. For example, a rise in the cost of steel and other essential materials increases the production cost for manufacturers, which often translates into higher prices for consumers. The supply chain disruptions experienced during the COVID-19 pandemic have had lasting effects on material availability and cost.Energy Costs

Energy-intensive technologies, such as carbon capture, require significant energy inputs, which can drive up the operating costs of flue gas treatment systems. As energy prices increase, especially in markets where fossil fuels are the primary energy source, the overall cost of operation for industrial facilities utilizing these systems can rise as well.

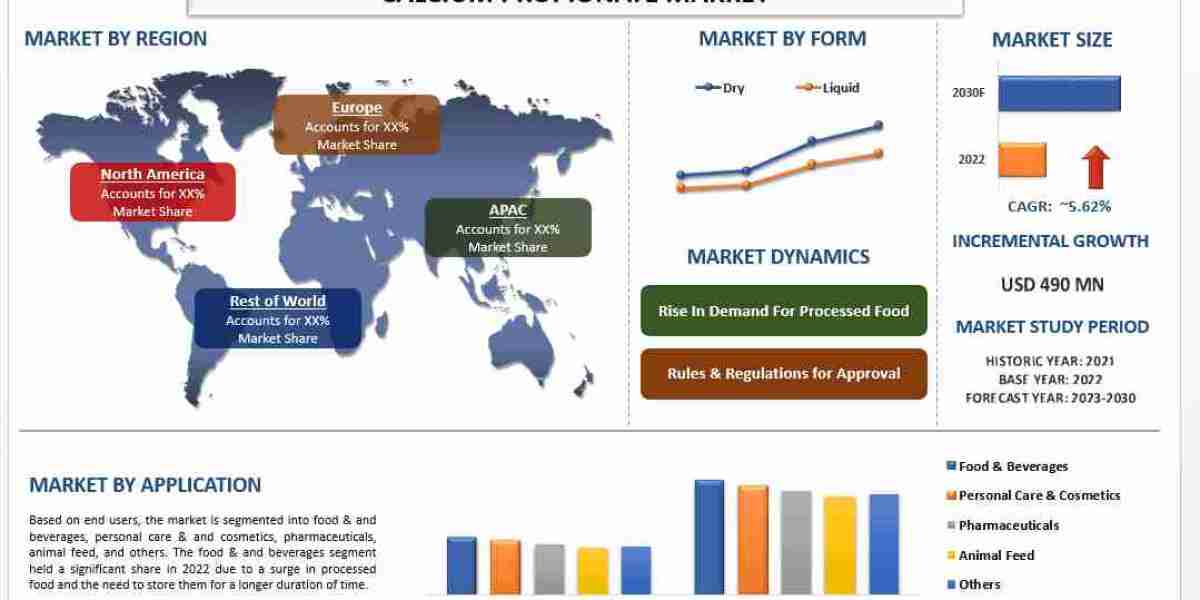

3. Regional Pricing Differences

Regional disparities in pricing are also notable within the industrial flue gas treatment market. Prices for flue gas treatment systems vary across different regions due to differences in labor costs, availability of raw materials, government subsidies, and regulatory frameworks.

Developed Markets

In developed markets like North America and Europe, higher regulatory standards and the availability of advanced technologies contribute to higher prices for treatment systems. However, these regions also benefit from government incentives for adopting clean technologies, which can offset some of the costs.Emerging Markets

In emerging economies, such as those in Asia-Pacific and Africa, the initial investment in flue gas treatment systems tends to be lower due to the lower labor costs and simpler technologies being used. However, these regions also face challenges such as regulatory inconsistencies, which can lead to variable pricing and delays in adoption.

Competitive Analysis

1. Market Players and Their Strategies

The industrial flue gas treatment market is competitive, with several global and regional players vying for market share. Key players in the market are focusing on product innovation, cost reduction, and forming strategic partnerships to enhance their competitive position.

Product Innovation

Leading companies are investing heavily in research and development to create more efficient and cost-effective solutions for flue gas treatment. Innovations in filtration, scrubbing technologies, and carbon capture systems are allowing companies to offer more scalable and flexible solutions for different industries.Strategic Partnerships and Mergers

Strategic collaborations and mergers have become a key strategy for companies looking to expand their market presence and technological capabilities. By partnering with regional firms or acquiring smaller players with complementary technologies, large corporations can enhance their service offerings and gain access to new markets.

2. Focus on Cost-Efficiency

To remain competitive, manufacturers are increasingly focused on reducing the overall cost of flue gas treatment systems while maintaining or improving efficiency. Companies are optimizing their production processes, improving supply chain management, and reducing energy consumption to lower the cost burden for industries.

- Local Manufacturing and Sourcing

Some companies are shifting towards local manufacturing and sourcing of components to reduce costs and mitigate risks associated with global supply chains. This approach not only lowers the cost of production but also helps meet region-specific regulatory requirements.

3. Increased Competition in Emerging Markets

The competitive dynamics in emerging markets are intensifying as both international and local companies compete for market share. Companies in these regions are often more focused on cost-effective and scalable solutions due to budget constraints in industries.

Price Sensitivity

In emerging economies, industries tend to be more price-sensitive, making cost-effective solutions more appealing. Local players often offer lower-cost alternatives, which can challenge the market positions of larger, international companies.Local Adaptation of Technologies

Some manufacturers in emerging markets are adapting existing technologies to meet the specific needs of local industries. This includes modifying flue gas treatment systems to cater to the particular types of emissions produced in these regions.

4. Role of Environmental and Regulatory Compliance

Environmental regulations remain a key factor driving competitive behavior in the market. As governments around the world impose stricter emission limits, companies that can offer technologies that help industries comply with these regulations are gaining a competitive edge.

- Government Incentives

In many regions, governments are offering financial incentives for industries to adopt cleaner technologies. This includes subsidies, tax rebates, and research grants that make the adoption of flue gas treatment technologies more affordable, benefiting both suppliers and end-users.

Final Thoughts

The industrial flue gas treatment market is shaped by dynamic pricing trends and fierce competition. While the costs of advanced technologies such as carbon capture and selective catalytic reduction are higher, companies are focused on product innovation and cost-reduction strategies to stay competitive. Regional pricing disparities, fluctuating material costs, and regulatory pressures further influence the market. As industries continue to focus on sustainability and compliance with environmental standards, the demand for flue gas treatment technologies is expected to remain strong, driving both market growth and innovation.