The welding consumables market has grown significantly over the years, driven by increasing industrialization, urbanization, and technological advancements across various industries. Welding consumables, such as electrodes, filler materials, fluxes, and wires, play a vital role in ensuring the durability and efficiency of welded structures. This article delves into the market’s segmentation, applications, and the strategic factors shaping its future growth.

Market Segments

The welding consumables market is primarily segmented based on product types, welding technologies, and end-use industries.

Product Types:

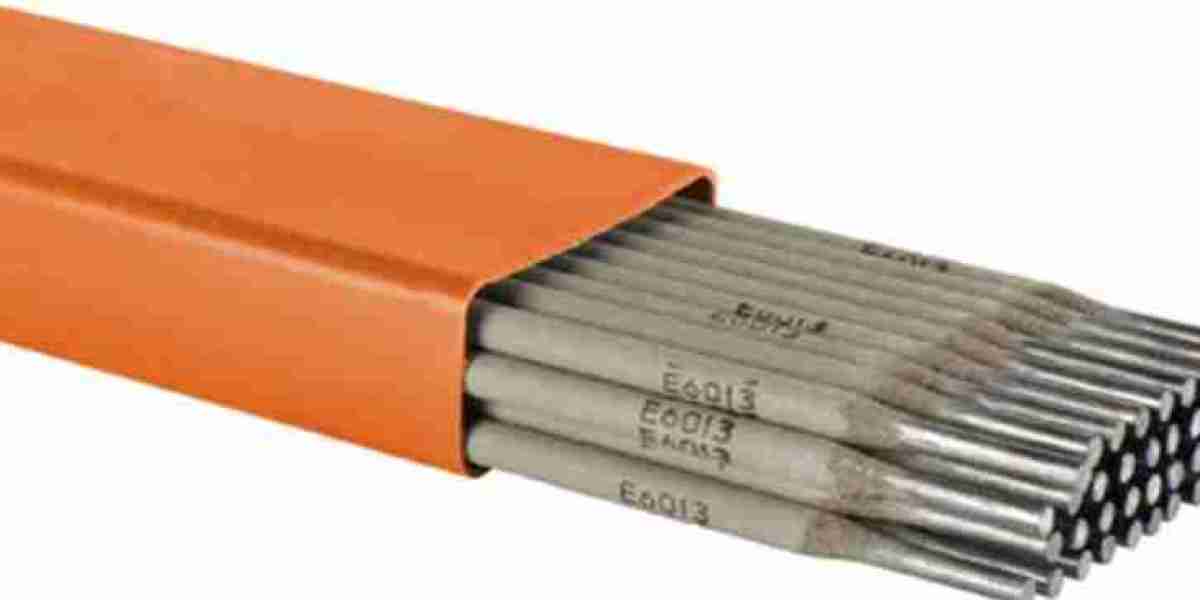

- Stick Electrodes: Popular for their versatility and suitability for outdoor welding.

- Solid Wires: Widely used in industrial fabrication due to their efficiency in high-volume production.

- Flux-Cored Wires: Ideal for heavy-duty applications requiring enhanced weld strength.

- SAW (Submerged Arc Welding) Fluxes and Wires: Preferred for precision welding in large-scale manufacturing projects.

Welding Technologies:

- Arc Welding: Dominates due to its affordability and versatility across industries.

- MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) Welding: Common in automotive and aerospace applications for their precision.

- Resistance Welding: Preferred for its speed and efficiency in mass production.

End-Use Industries:

- Automotive: Rising demand for lightweight and durable vehicles drives the use of advanced welding consumables.

- Construction: The booming construction sector emphasizes high-strength materials, boosting the market.

- Oil & Gas: Welding consumables are essential for pipeline construction and maintenance.

- Aerospace and Shipbuilding: Precision welding is critical in these high-stakes industries.

Applications

Welding consumables are integral to various applications, including infrastructure development, machinery fabrication, and energy production. The construction sector relies on these materials to meet structural integrity and safety standards in bridges, buildings, and tunnels. In automotive manufacturing, they enable the production of lightweight and durable components, aligning with the industry’s shift toward electric and hybrid vehicles. The energy sector, especially renewable energy projects like wind turbines, also relies heavily on welding consumables.

Growth Strategies

Technological Advancements:

Innovations in welding technologies, such as laser and robotic welding, have revolutionized production processes. These advancements improve efficiency, reduce wastage, and enhance the quality of welded joints, driving the demand for advanced consumables.Sustainability Initiatives:

With increasing focus on sustainability, the market is shifting towards eco-friendly consumables. Lead-free and low-emission products are becoming a priority, particularly in developed economies with stringent environmental regulations.Regional Expansion:

Emerging economies in Asia-Pacific, the Middle East, and Africa offer significant growth opportunities due to rapid industrialization and urban development. Expanding distribution networks and localized manufacturing units in these regions are critical for capturing market share.Customization and Industry-Specific Solutions:

Companies are focusing on developing industry-specific welding consumables to meet unique requirements in aerospace, automotive, and energy sectors. Tailored solutions enhance efficiency and cost-effectiveness, creating a competitive edge.Digital Integration:

Integrating digital tools like welding monitoring systems and IoT-enabled consumables is transforming the market. These technologies improve precision and help in tracking performance, ensuring better productivity.

Future Outlook

The welding consumables market is poised for steady growth, driven by advancements in welding techniques, a surge in infrastructure projects, and the rising adoption of electric and hybrid vehicles. The focus on automation and sustainability will further define the trajectory of the market. Emerging technologies like 3D printing in welding applications and hybrid welding processes are likely to shape the future landscape, offering enhanced productivity and reduced costs.

In conclusion, the welding consumables market is evolving to meet the demands of modern industries. Companies that prioritize innovation, sustainability, and regional expansion will remain competitive in this dynamic market.