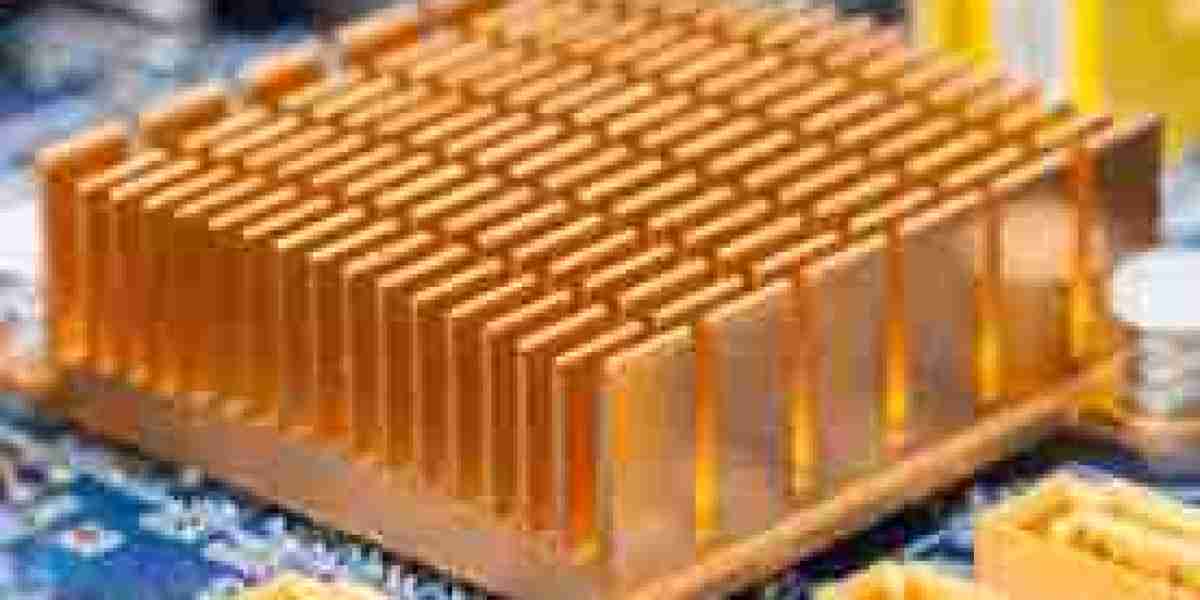

When selecting a Die Cast Heatsink Supplier, it's crucial to ensure that you are partnering with a reliable and experienced provider that can meet your specific needs. Heatsinks are vital components in thermal management systems, especially in industries such as electronics, automotive, and telecommunications. A poor-quality heatsink can affect the performance and longevity of your devices. Therefore, understanding the essential factors to consider when working with a supplier is key to ensuring that you receive high-quality products that meet your cooling requirements.

1. Quality and Material Standards

One of the most important considerations when choosing a Die Cast Heatsink Supplier is the quality of the materials used. Die casting involves pouring molten metal into a mold to form heatsinks, and the material must be durable enough to handle the specific cooling needs of your system. Be sure that the supplier uses high-quality materials, such as aluminum or copper, which have excellent thermal conductivity properties. The supplier should also adhere to industry standards to ensure the reliability and efficiency of the heatsinks.

2. Customization Options

In many cases, off-the-shelf heatsinks may not meet the specific needs of your applications. Customization is a key factor when working with a Die Cast Heatsink Supplier. Suppliers that offer bespoke designs can create heatsinks that fit your exact specifications, such as shape, size, and mounting options. Custom solutions ensure optimal thermal management for your unique application, and it’s essential to work with a supplier who can deliver tailored designs based on your needs.

3. Lead Times and Delivery

Timely delivery is critical, especially when dealing with tight production schedules. When working with a Die Cast Heatsink Supplier, it’s important to discuss lead times and delivery expectations upfront. Delays in receiving the required components can hinder project timelines, so ensure that the supplier has a reputation for reliability and on-time delivery.

4. Manufacturing Capabilities

The supplier’s manufacturing capabilities are another crucial factor to consider. Look for a Die Cast Heatsink Supplier with the ability to handle large-volume orders or those with complex specifications. Suppliers who invest in advanced equipment and have experienced engineers are better equipped to deliver high-quality products that meet performance requirements.

5. Customer Support and Communication

Effective communication with your supplier is vital to ensure the success of your project. Choose a Die Cast Heatsink Supplier that provides excellent customer support, is responsive to your inquiries, and can assist you with any technical issues that may arise during the production process. A supplier that values transparency and collaboration will be a long-term partner in your business.

By keeping these considerations in mind, you can select a Die Cast Heatsink Supplier who will help optimize your thermal management solutions and contribute to the overall success of your products