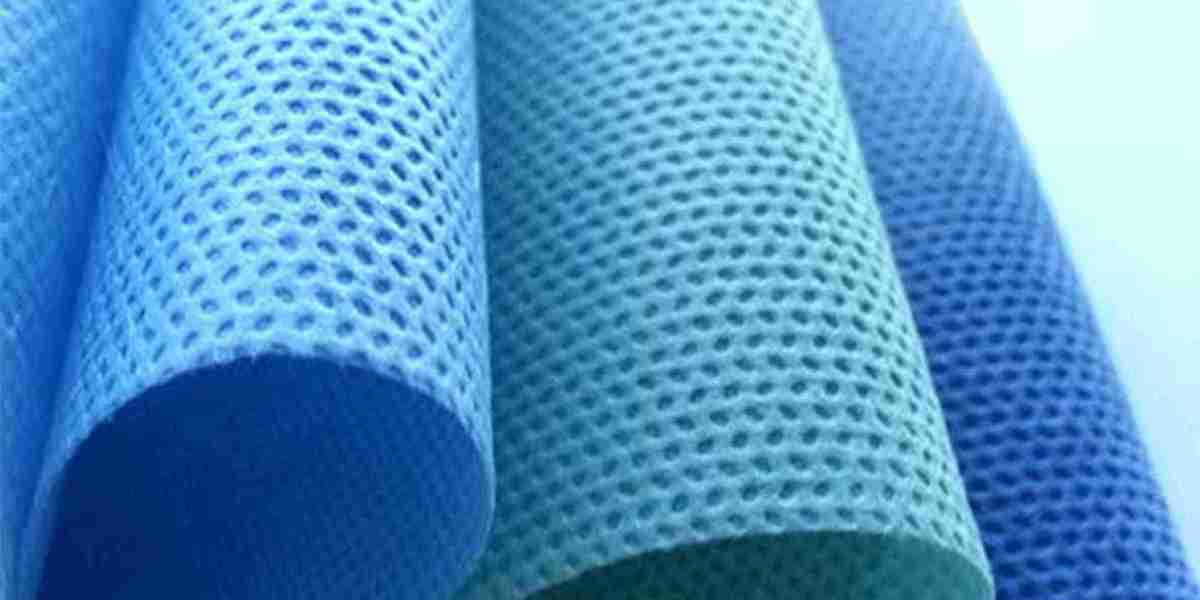

The non-woven fabric market has experienced substantial growth due to evolving technologies, rising demand across key industries, and a growing focus on sustainability. As an essential material in healthcare, automotive, textiles, and hygiene products, non-woven fabrics are gaining traction due to their versatility, eco-friendly characteristics, and cost-effectiveness. This market landscape continues to evolve with the integration of cutting-edge technologies, innovations, and new business strategies that aim to meet diverse consumer needs globally.

Technological Advancements in Non-Woven Fabric Production

- The production of non-woven fabrics has evolved significantly with innovations in manufacturing technologies such as spunbond, meltblown, and air-laid processes.

- These advanced technologies enable the production of high-quality fabrics with customized properties for different applications.

- Spunbond non-woven fabrics are widely used for their high strength and durability, while meltblown fabrics are essential in filtration products due to their fine fiber structure.

- The development of technologies like bi-component spinning and electrospinning has paved the way for high-performance non-woven fabrics used in technical and industrial applications.

Rising Demand from Healthcare and Hygiene Products

- The healthcare sector is a major driver in the non-woven fabric market, as these materials are ideal for producing medical gowns, masks, surgical drapes, and sterile packaging.

- Non-woven fabrics offer critical benefits in hygiene products such as diapers, feminine care, and adult incontinence products due to their superior absorbent properties and comfort.

- Increased demand for single-use medical products, especially during and after the COVID-19 pandemic, further fueled market growth.

- As healthcare standards improve globally, non-woven fabrics are increasingly preferred for their hygienic and disposable nature.

Environmental Impact and Sustainable Production

- With growing concerns over environmental sustainability, manufacturers are exploring biodegradable and recyclable alternatives to traditional synthetic non-woven fabrics.

- Biodegradable options made from natural fibers, such as cotton, jute, and flax, are gaining traction due to their eco-friendly attributes.

- Manufacturers are shifting toward eco-conscious materials such as polylactic acid (PLA) and recycled polyethylene terephthalate (rPET) fibers.

- Efforts are being made to ensure that non-woven fabrics are compostable or can be recycled, reducing their impact on landfills and the environment.

Market Dynamics Driven by Consumer Trends

- As consumers become more conscious of environmental and health issues, the demand for sustainable and non-toxic non-woven fabric products is increasing.

- The growing preference for natural and organic materials in products such as baby wipes, cleaning wipes, and eco-friendly packaging is shifting the market toward greener alternatives.

- Additionally, the convenience of disposable products in the form of wipes, hygiene products, and medical supplies has created a continuous need for non-woven fabrics.

- With an emphasis on health, comfort, and sustainability, consumer preferences are shaping market trends in the non-woven fabric industry.

Regional Market Landscape and Growth Potential

- The Asia-Pacific region is a dominant player in the non-woven fabric market, driven by the rapid industrialization of countries like China and India.

- North America and Europe are also significant contributors, particularly due to the high demand from the healthcare and automotive sectors.

- Emerging economies are seeing a surge in demand for non-woven fabrics as their economies expand and healthcare standards improve.

- The rising industrialization in Latin America and the Middle East offers promising growth opportunities for non-woven fabric manufacturers.

- Local production capabilities, along with the increasing popularity of sustainable products, are expected to strengthen the market presence in these regions.

Challenges in the Non-Woven Fabric Market

- The high production costs associated with some advanced non-woven fabrics, especially biodegradable options, pose a challenge for manufacturers.

- The price volatility of raw materials, such as oil-based synthetics used in fabric production, impacts the overall cost structure.

- The limited recycling options for non-woven fabrics, particularly those made from synthetic materials, require ongoing research into effective waste management and recycling technologies.

- Competition from low-cost manufacturing regions, particularly in Asia, creates pricing pressure for companies in developed markets.

Future Outlook for the Non-Woven Fabric Market

- The future of the non-woven fabric market looks promising, with growth expected to continue across various industries.

- The increasing focus on sustainability and the demand for eco-friendly, high-performance fabrics will shape the market's direction.

- With advancements in production technologies and the development of new materials, non-woven fabrics will continue to gain popularity for their unique properties and versatile applications.

- Manufacturers will focus on reducing production costs, improving recycling options, and meeting consumer demand for sustainable solutions to ensure long-term growth in the non-woven fabric market.